Application of aluminum plate in Hubble Space Telescope

Today marks the 27th anniversary of the launch of the Hubble Space Telescope, which has made outstanding contributions to human scientific research in space. What are the applications of 4x8 aluminum sheet in the Hubble Space Telescope?

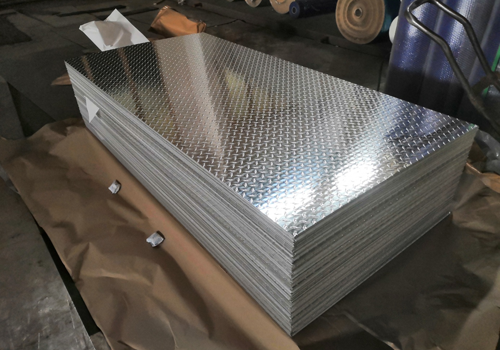

aluminum sheet

For the Hubble Space Telescope, mirrors are very important. The mirror-polished coating of the telescope uses an aluminum plate with a thickness of 75 nm as a reflector. Lightweight aluminum sheets are used as the telescope's instrument and housing. The application of aluminum plates in the Hubble Space Telescope is characterized by strong reflectivity and light weight. Aluminum sheets are usually used for aluminum sheets: lighting, solar reflectors, building exteriors, interior decoration, ceilings, walls, furniture, cabinets, elevators, signs, nameplates, luggage, interior and exterior car decoration, home appliances, aerospace and military. Today we will talk about the application of aluminum sheet in the aviation field. At present, the total amount of aluminum in the aerospace field accounts for about 5% of the total aluminum consumption worldwide. However, due to the large consumption of aluminum sheets in the aerospace field and the high technical content of aluminum, this field has become a hot spot for aluminum companies. . The C919 aircraft project uses medium and Thin Aluminum Sheet, and the products are mainly 7 series aluminum alloys. The requirements for aluminum plates in the aerospace field are not only reflected in the characteristics of high metallurgical quality, high performance technical indicators and specifications, and complex dimensions, but also in their structure, performance, surface accuracy, especially strength, plasticity, corrosion resistance and fatigue resistance. The performance is extremely strict requirements. 7005 and 7075 aluminum alloy sheets are the highest level products in the aeros pace field 7 series of aluminum alloys, and the heat treatment process can be improved. For example, 7075 aluminum plate has high strength (high temperature strength and low temperature strength are better than other aluminum alloys), and it has good plasticity after solution treatment, so it has excellent comprehensive mechanical properties. 7075 aluminum is mainly used to manufacture high-strength, high-corrosion-resistant high-stress plane structures, such as the upper and lower wing sidewall panels and purlins of aircraft. At present, the global consumption of aviation aluminum alloy sheets is estimated to be 780,000 tons, and it is estimated that by 2020, the global aviation aluminum sheet will be 1 million tons.

How to prevent scratches on the surface of aluminum plate?

Care must be taken when using the forks to feed the profiles from the unloading path to the unloading bed, as many people have caused some damage to the 4x8 aluminum sheet due to excessive speed. Pick up the aluminum divider placed on the bed, do not tug the boat, this will cause damage to the aluminum appearance. There are factors that pass through the damage formation process, which is also the case with aluminum renders that damage renders. Put some small debris on the bed surface of the discharge rail, and then put the aluminum sheet, it will definitely cause damage to the appearance of the aluminum sheet.

Different types of aluminum alloys and their applications

According to the processing method, Alloy Aluminum sheet can be divided into two categories: deformed aluminum alloys and cast aluminum alloys.

Deformed aluminum alloys are further divided into non-heat treatable reinforced aluminum alloys and heat treatable reinforced aluminum alloys.

Cast aluminum alloys can be divided into aluminum-silicon alloys, aluminum-copper alloys, aluminum-magnesium alloys, aluminum-zinc alloys and aluminum-rare earth alloys according to their chemical composition.

There are nine series of deformed aluminum alloys:

1.1000 series

The 1000 series is the series with the most aluminum of all the series. The purity can reach more than 99.0%. Its classics are 1050 aluminum plate and 1060 aluminum plate.

It is characterized by low price, good electrical conductivity and high corrosion resistance. It can be used in the manufacture of electrical appliances, chemical equipment, signs, etc.

2. 2000 Series

The 2000 series is known for its high hardness. The representative is 2024, 2A16, 2A02. The 2000 series belongs to aviation aluminum.

3. 3000 series

The 3000 series belongs to the aluminum-manganese alloy, which is a series with anti-rust function. Its representatives are 3003 aluminum plate and 3A21. It can be used to make water storage tanks, cookware and pipes, etc.

4.4000 series

The 4000 series is a series with higher silicon content. Typically the silicon content is between 4.5% and 6.0%. It has good heat resistance and abrasion resistance. It can be used as building material, machine parts and welding material.

5.5000 series

The 5000 series belongs to the commonly used 4x8 aluminum sheet series. The main element is magnesium, and the magnesium content is between 3-5%. The main features are low density, high tensile strength, high elongation and good fatigue strength, but cannot be heat treated. It is used to make fuel tanks, oil pipes, ship parts, etc.

6.6000 series

The 6000 series contains mainly magnesium and silicon. It is a cold-treated forged product with high corrosion and oxidation resistance. Its representative is 6061 aluminum plate.

It can be used in various industrial structural parts that require high strength, weldability and corrosion resistance, such as trucks, buildings and ships.

Why are the shapes of aluminum lattice panels different?

In fact, aluminum gingham with different patterns and shapes has different aluminum materials.

1. Pattern of compass aluminum alloy plate: non-slip 4x8 aluminum sheet, which is similar to Wujin, but it is not often used.

2. Five-bar aluminum pedal: It has good anti-skid ability and is widely used in construction, platform design, etc. The surface patterns are arranged according to five relatively parallel reliefs, and each pattern has an angle of 60-80 degrees with other patterns, so this pattern has excellent anti-slip performance. It is commonly used in China for anti-skid. Using this, the anti-skid effect is good, and the price is cheaper.

3. Anyone who buys an aluminum plate can call the aluminum plate a hemispherical pattern, and the surface presents a pattern of small balls, like small pearls, so the aluminum plate can be a pearl pattern aluminum plate. Mainly used for packaging. The appearance is more beautiful. Due to the particularity of the pattern, the strength of the Aluminum sheet is much higher than that of other series of patterns.

4. Other aluminum patterns: wave pattern plate, water corrugated pattern aluminum plate, corrugated pattern aluminum plate (aluminum and variable tile), rattan screen pattern aluminum plate, three-dimensional triangular pattern aluminum plate, strip pattern aluminum plate, aluminum pebble pattern plate, aluminum tread pattern Plate, triangular stucco embossed aluminum plate, butterfly pattern aluminum plate, etc.

What Is 3003 Aluminum Used for

3003 aluminum is a common kind of Al-Mn Series Alloy. Owing to Mn element, 3003 aluminum is of excellent rust-proof properties and is also known as rust-proof aluminum.

It is easy to bend and of good weldability properties,formability and solubility. It is an alloy that is not heat treatable and can only develop strength from cold working. The strength of 3003 4x8 aluminum sheet is about 10% higher than 1100. It also has high plasticity in the annealing state, good plasticity in the semi-cold hardening state, and low plasticity in the cold hardening.

What Is 3003 aluminum used for? Because of these 3003 aluminum properties, 3003 aluminum is mainly used for low load parts requiring high plasticity and good weldability in liquid or gaseous media, such as fuel tanks, gasoline or lube oil conduits, various liquid containers and other small load parts made with deep drawing.

The common forms of 3003 aluminum is 3003 aluminum foil, 3003 aluminum sheet and plate. Because of its excellent rust-proof properties, 3003 aluminum foil is often used in wet environments like outer packaging, refrigerator, air conditioning ventilation ducts,etc.

3003 aluminum sheet is commonly used in boats, naval ships, automobile and aircraft welded parts, pressure vessels, refrigeration equipment, television towers, drilling equipment,missile components, armor, etc.

As a professional aluminum sheet manfuacturer, plate and foil, Haomei can offer you 3003 aluminum sheet with best price and air conditioner foil of different specifications.

Where Can I Buy Aluminum Sheet Metal

Considering where to buy aluminum sheet metal? Please look at HUAWEI Aluminum as your aluminum sheet manufacturer! HUAWEI Aluminum provides 1000-7000 series of 4x8 aluminum sheet, super large-format CNC machining equipment to assist aluminum plate processing, professional technical engineers provide design drawings, mold proofing, processing and production, and super-perfect pre-sales and after-sales consultation, so that you have no worries!

After 25 years of production, processing and sales of aluminum sheets and other materials, HUAWEI Aluminum has provided thousands of enterprises and units with high-quality aluminum sheet metal metal products and services. Customers generally praise. No matter what the processing requirements are, please state them first. We, HUAWEI Aluminum, will provide the processing plan that meets the expectations as much as possible according to our own equipment configuration and technical reserves. How does HUAWEI Aluminum ensure the quality of the aluminum sheets it sells?

1. Provide original material proof

2. Provide third-party inspection agencies such as SGSBV to provide inspection

3. Sign the purchase contract and provide the goods in strict accordance with the contract

4. Review and check before leaving the warehouse to ensure that the product will not go wrong

5. The product should be carefully packaged before leaving the warehouse to ensure that it will not be damaged during transportation.