Full sheets – Embossed Aluminum Black Diamond Plate Sheets – Black Cosmetic Grade .025 cosmetic grade aluminum diamond plate sheets. Perfect for black diamond plate wall panels, diamond plate wainscoting, or diamond plate ceiling tiles. Great for Man Caves, garages, workshops, vehicles, trailers, home gyms, and MUCH more! This cosmetic grade embossed diamond plate sheet can be rolled for shipping and storing. We are happy to provide custom cuts and have a great discount on bulk purchases. See our matching diamond plate outside corner pieces and inside corner pieces to complete your piece. This item also matches the diamond plate switch plates and outlet covers that we carry.

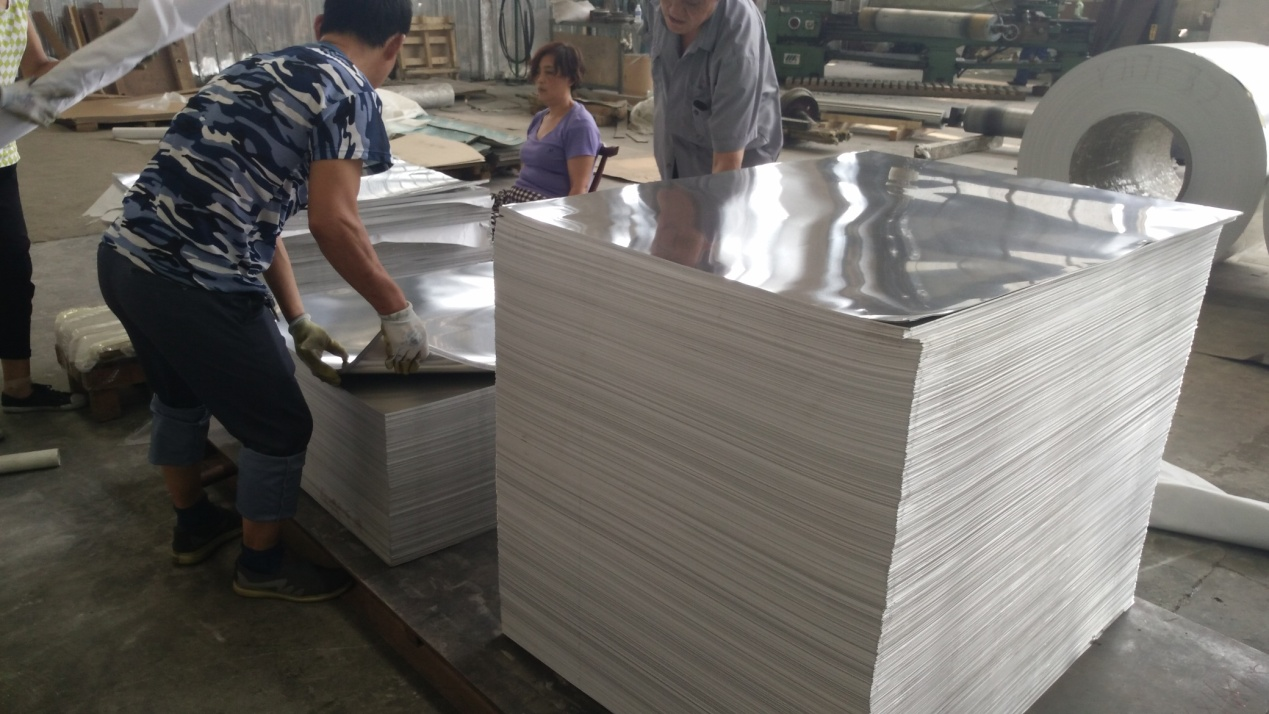

These sheets are NOT aluminum foil. Aluminum foils are in the .002 to .003 thickness range. These are NOT a plastic diamond plate imitation that will crack over time. Don’t settle for faux diamond plate wallpaper when you can have real

black diamond plate for less.

These thin diamond plate sheets will add flair and protection to your walls. They are made from .025 (just under 1/32″) flexible aluminum sheets that have a high quality painted surface suitable for indoor or outdoor applications. The painted surface is building material quality painted aluminum that will NOT flake or chip when cutting or bending.

These sheets are rolled with a loose diameter and boxed for shipping and are guaranteed not to crimp. We have custom heavy duty boxes that will protect your products from our warehouse to your doorstep. A plastic PVC coating allows you to install the sheets safely and then remove to keep fingerprints and adhesives off of the finished side.

You won’t find an easier product to work with. Tin snips will work for short cuts and for longer lines, a hand shear will easily cut through. Check out our other top trim, corner guards and diamond plate switch covers to complete your project.

There are various applications of

aluminum sheets that you can use in your interiors and exterior. It is one of the most popular metals in the present era.

Some of the popular usages of aluminum are as follows:

Aluminum is extensively used for roofing as it is lightweight and can withstand corrosion. It is sturdy and helps to protect your roof from damage.

You can use aluminum sheets to cover the ceiling of your house, and it not only looks decorative but also protects your roof from further damage.

Since aluminum is lightweight and water-proof, you can use it for the railings of your balcony.

The soft drinks that you drink from cans the packaged food have all-aluminum coverings, and it keeps the food and the drinks safe.

Most of the lamp reflectors that you see today are all made of aluminum, and it is because they have an excellent reflective property.

Most of the walkways and covered shelters that you see have an aluminum sheet covering. It protects us from heat and rainfall and is an ideal material for indoor and outdoor protection. Since the aluminum plate is chequered, you can protect it from slipping.

It is advantageous in corridors and car-packs as it can withstand wear and tear.

https://oblq.online

https://dvtel.online

https://housta.online

https://acarapassion.site/

https://pizzerialabellastoria.nl/

https://www.alufoil.cn/

https://lionsalu.github.io/

https://hwalum.github.io/

Aluminum sheet is widely used in transportation, decoration, household appliance, packaging,etc., due to its excellent performance. More and more enterprises like to replace the original production material with aluminum sheet in order to obtain better product performance. How much do you know about the 4x10 aluminum sheet?

Alloys

In terms of chemical composition,

6060 aluminum sheet are currently divided into 1-8 aluminum alloys internationally. Except that 1xxx belongs to pure aluminum, the other 7 series are alloys of different elements, such as 2xxx aluminum-copper alloy, 3xxx aluminum-manganese alloy, and 5xxx aluminum-magnesium alloys, 6xxx aluminum-magnesium-silicon alloys,etc.

Thickness

As for the thickness, there are two kinds: thin aluminum sheet and thick aluminum plate. The common thin plate thickness is between 0.2-10mm, and the thickness of thick plate is between 10mm-120mm. If it is higher than 120mm, it is an unconventional specification and needs to be customized.

Size

The sizes we often hear are 4x8, 4x10 and 5x10. 4’x10’ also called 48”x120”, indicate 4 foot and 10 foot. 4’x10’ stands for 4 foot and 10 foot. 5’x10’ stands for 5 foot and 10 foot. 1 foot= 304.8 mm, 4’=1219 mm, 5’ = 1524,10’= 3048mm.

4x10 aluminum sheet indicates the width of aluminum sheet ×length = 4 foot × 10 foot = 1219mm × 3048mm. 4x8 aluminum sheet is 1219mm×2438 mm. 5x10 aluminum sheet is 1524 mm ×3048 mm.

Aluminum sheet weight

The weight of the aluminum plate = the thickness of the aluminum plate, the length of the aluminum plate, the width of the aluminum plate, and the density of the aluminum plate The weight of a 3mm*1000mm*2000mm aluminum plate is: 3*1*2*2.7=1.62kg.

Aluminum sheet price

Aluminum plate price = aluminum ingot price + processing fee, in which the aluminum ingot price is constantly changing with the international market and the processing fee is slightly different for each aluminum plate manufacturer. Welcome to leave message below to inquire

Differences in their material composition:

The chemical composition and processing properties of

6060 aluminum sheet and 6063 aluminum sheet are similar, but not identical.

Material composition of 6060 aluminum plate: Si: 0.3-0.6; Iron: 0.1-0.3; Cu: 0.1; Mn: 0.1; mg: 0.35-0.6; Chromium: – Zinc: 0.1; ; ale: quantity.

Material composition of 6063 aluminum plate: aluminum al: balance; si: 0.20-0.6; Cu: ≤0.10; mg: 0.45-0.9; Zn: ≤0.10; Mn: ≤0.10; ti: ≤0.10; Cr: ≤0.10; Fe : 0.000 ~ 0.350; Note: Single: ≤ 0.05; Total: ≤ 0.15;

Features of 6060 aluminum plate:

Tensile strength σb (MPa): ≥ 470

Conditional yield strength σ0.2 (MPa): ≥420

Elongation δ5 (%): ≥ 6

Features: 1. High strength heat treatable alloy. 2. Good mechanical properties. 3. Good usability. 4. Easy to process and good wear resistance. 5. Good corrosion resistance and good oxidation resistance

Features of 6063 aluminum plate:

6063 aluminum plate belongs to aluminum magnesium silicon alloy and is widely used. Especially in the construction industry, it is the most promising alloy. Good corrosion resistance, excellent weldability, good cold workability and moderate strength. Luhua Aluminum's 6063 aluminum plate manufacturers are of high quality and low price.

6063 aluminum sheet is a low-alloy aluminum-magnesium-silicon high plasticity alloy with many properties:

1. Heat treatment strengthening, high impact toughness.

2. It has excellent thermoplasticity and can be extruded into complex structures at high speed. such as thin walls. It also has a wide quenching temperature range and low quenching sensitivity, as long as the temperature is higher than the quenching temperature after extrusion and forging demoulding. Can be water sprayed or water quenched.

I am installing radiant tubes in the floor joist pockets that I have added on my first and second floors.

I've been told that I need to use an

Aluminum Heat Transfer Plates with piping for maximum support and heating efficiency. I've also been told that I just need to connect the ducts to the underside of the subfloor by any means and then insulate the top two to three inches of the cavity to make sure the warm air there moves up through the floor and doesn't fill the room below cavities and ceilings, waste heat.

What are the best practices? How much heating efficiency do I gain or lose anyway?

It's a question of efficiency

Boards with tiny air gaps and insulation below will transfer heat to the floor most efficiently.

A board without insulation will transfer heat above and below.

Tubes with air gaps and good insulation will transfer more heat to the floor than uninsulated boards. Insulated panels transfer more heat to the floor than pipes that have air gaps and then insulate.

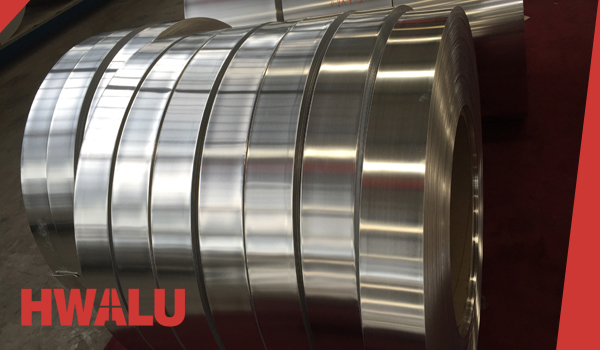

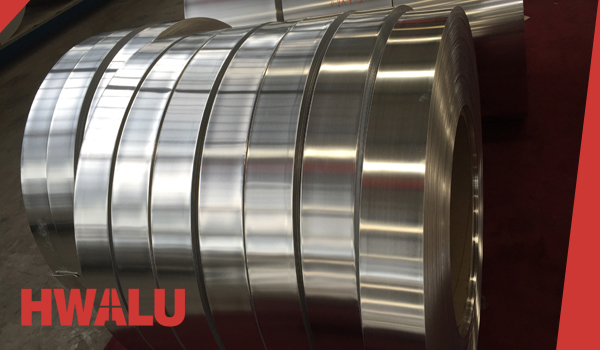

The aluminum strip is an aluminum alloy with an aluminum content of 99.5% or more. Aluminum strips are made by cutting aluminum coils.

Aluminum strip refers to a strip-shaped product made of aluminum as the main raw material and mixed with other alloying elements. The cross section is rectangular and the thickness is uniform, greater than 0.20 mm. Typically, the edges are sawn on site and delivered flat. Commonly used alloy series for

aluminum strip are 1000 series, 3000 series, 5 series, 8 series, etc. Common aluminum models are 1050, 1060, 1070, 1100, 3003, 3004, 5005, 5052, 8011, etc. Commonly used states are O-type and H-type. o is soft, H is hard. o and H can be followed by numbers to indicate hardness and degree of annealing.

Aluminum strip is an important basic material for the development of the national economy. It has a high aluminum content and is also known as pure aluminum strip in the industry. Because this series of aluminum strips have good plasticity, corrosion resistance, electrical conductivity and thermal conductivity. Aluminum strip is more suitable for further stamping, extrusion and deep drawing. Products made of various aluminum foils, as well as various electronic, lamps, nameplates, electrical products.

Thin aluminum tape has many uses, such as aluminum pipes, cables, optical cables, transformers, heaters, blinds, etc.

Thanks to technologically advanced suppliers, we have been able to supply a wide range of aluminum strips. These are made with aluminium wire and the latest machines and tools. We offer a wide range of standard sizes and grades of steel strip widely used in the manufacture of engine plates.

More products please see the link:

https://www.alufoil.cn/

https://hw-matels.com/

https://zelarestaurant.nl/

https://skyfun.be/

https://pastificiosole.it/

https://bistrodesteiger.be/

1060 aluminum plate manufacturer-Huawei Aluminum is an enterprise specializing in the production of 1060 aluminum plate. The price of 1060 aluminum plate is higher than the price of similar raw materials. The reason is that its characteristics, such as the Peugeot characteristics of aluminum, anti-rust and anti-corrosion properties, ensure that the survivability of aluminum is more than half higher than that of the same raw material, especially in harsh environments such as humidity. In addition, regarding the plasticity of the aluminum sheet, the 1060 aluminum sheet can have various processing forms, such as a pressed tiled aluminum sheet formed after the pressing tile processing, and an embossed aluminum sheet formed after the embossing processing. There are many forms and states to choose from.

Recently, the quotations of 1060

aluminum sheet manufacturers have fluctuated greatly. One is the influence of the market price of aluminum ingots, and the other is because of the shortage of 1060 aluminum sheets. The price of 1060 aluminum plate is closely related to the price of aluminum ingots. If the quotation of the 1060 aluminum plate manufacturer is lower than or approximately equal to the price of the aluminum ingot, it is necessary to consider whether it is a quality problem or the aluminum content has not been reached. Avoid cutting like leeks. The processing cost generated by the price of aluminum sheets requires the formation of aluminum sheets through cumbersome processes and a series of processing procedures on the basis of aluminum ingots. 1060 aluminum plate is a series of 1 series pure aluminum plate with very high aluminum content. Due to the relatively simple process and mature technology, the processing price is relatively low.

Aluminium sheets produced by aluminium sheet 1060 manufacturers have flat shapes and excellent geometric dimensions. At the same time, the surface gloss is high, the alkali cleaning effect is good, and it can reach the A level of the water brush test. 1060 aluminum sheet has good elongation and tensile strength, can meet the conventional processing requirements (stamping, drawing) and high formability.

Today, Aluminium HW will come to tell you about popular science, what are the common series of aluminium sheets? What are the characteristics and applications of different series of aluminum plates such as 1 series aluminum plate, 3 series aluminum plate and 5 series aluminum plate?

①1××× series

It is industrial pure aluminum, and it is a brand series with the highest aluminum content. The aluminum content is not less than 99.00%. It has good elongation, tensile strength, plasticity and corrosion resistance. The production process is relatively simple, the production technology is relatively mature, and the price has a huge advantage, but the strength is low and it is easy to be deformed by compression.

Mainly used for signs, billboards, wall decoration, kitchen utensils, chemical equipment, electronic devices and other products that do not require high strength. It is a series commonly used in conventional industries.

At present, the 1100, 1050 and 1060 series of aluminum plates are widely used in the building decoration industry.

③3××× series

It is an aluminum-manganese alloy aluminum plate (Al-Mn), also known as an anti-rust aluminum plate, with manganese as the main alloying element, its content is between 1.0-1.5%, its strength is higher than that of the 1 series aluminum plate, and it has good formability, weldability, Corrosion resistance.

It is mainly used in industries with high requirements for anti-corrosion and anti-rust, such as building decoration industry, electronic manufacturing industry, automobile manufacturing industry, etc. It is an industrial anti-rust aluminum plate with a wide range of domestic applications.

At present, 3003, 3004 and other series of aluminum plates are widely used in the building decoration industry.

⑤5××× series

It is an aluminum-magnesium alloy aluminum plate (Al-Mg), with magnesium as the main alloy element, with good processing and forming performance, corrosion resistance, welding performance, etc., and is widely used in conventional industries because of its low density and weight than other series Aluminum plate is light and is also commonly used in ship structures, aircraft fuel tanks, automobile fuel tanks, etc.

At present, the 5052 series of aluminum plates are widely used in the building decoration industry.

⑥6××× series

It is an aluminum-magnesium-silicon alloy aluminum plate (Al-Mg-Si), with magnesium and silicon as the main alloying elements, with medium strength, good corrosion resistance, good weldability and oxidation effect, and is mainly used for corrosion resistance and oxidation resistance. High industry and products.

For more information on aluminum plates, please read

https://hw-matels.com/

https://kringloopberkelenrodenrijs.nl/

https://vanderhoornhovenier.nl/

https://camping-deroos.nl/

https://decurieuzecollectie.be/

https://wellra.pl/

https://bouwbedrijfjosmoonen.nl/

لإنتاج مواد البناء ، يمكن لشركة جنرال موتورز أن تقدم آلات التكسير الأساسية مثل الكسارة الفكية ، الكسارة الصدمية ، الكسارة المخروطية وآلة صنع الرمل. حتى الآن ، قمنا بتطوير 10 سلاسل والتي تشمل أكثر من 100 نموذج من الماكينات التي يمكن مطابقتها بحرية وذلك لتلبية المتطلبات المختلفة للإنتاج وأنواع مواد البناء. مطحنة PC Hammer ، MTW ، MTM متوسطة السرعة مطحنة Trapezium ، مطحنة الكرة والمطحنة العمودية LUM ، LUM تغطي جميع متطلبات إنتاج المساحيق الخام والناعمة والمتناهية الصغر في مجال الطحن الصناعي. يمكن تحقيق إنتاج تركيبة مجانية من 0 إلى 2500 شبكة. بغض النظر عن الصناعة التي تعمل فيها ، الكيمياء ، الطاقة ، مواد البناء أو مجال التعدين ، ستلبي جنرال موتورز دائمًا جميع متطلباتك. more detials please visit : https://lardeqo-restaurant.be https://cafekomeet.be https://msgauss-pir.de https://casamali.be https://bellevue-beaune.fr https://lebistrotdepierre.fr https://ar.pizzarosa91.fr https://framingmymessage.nl https://meano.co.za https://thierry-drapeau.fr https://burgbergschaenke.de https://eat-well.cz https://ecopowerproelectrical.co.za https://weinhaus-oberhausen.de https://first-auto-glas.de https://fa.pagetconfort.fr https://restaurant-le9.fr https://le-barkleys.fr https://tryskacimaterial.cz https://levalgirard.fr

إن قدرة التكسير لمعدات الكسارة المطرقية العكسية كبيرة جدًا ، والمنتجات المنتجة عمومًا تكون مكعبة ، والتي يمكن سحقها بشكل انتقائي ، لذلك فقد تم استخدامها على نطاق واسع في العديد من الصناعات ، سواء كانت أساسًا كبيرًا للطاقة الكهرومائية في بناء الطرق عالية السرعة ، أو في تطوير المناجم ، من الضروري استخدام كسارة المطرقة العكسية لسحق الأحجار الكبيرة.هذه الكسارة المطرقية لها تأثير جيد للغاية. تكرار الاستخدام في الصناعة هو الأكثر ، في الوقت الحاضر ، ينتج العديد من الشركات المصنعة كسارات مختلفة قابلة للانعكاس. يمكنك الاختيار وفقًا لاستخدامك الفعلي. إذن ما هي الأسباب العامة للضرر الناتج عن كسر المطرقة العكسية؟

بادئ ذي بدء ، أي كسارة لها نطاق استخدام فريد ، لذا فإن كسارة المطرقة العكسية ليست استثناءً. فهي تتطلب ألا يتجاوز حجم الحجر الذي يدخل الماكينة النطاق الذي يمكن أن تتحمله. إذا كان شكل الخام كبيرًا جدًا ، فسيظهر في حالة الانسداد ، يجب إيقاف الماكينة تمامًا في هذا الوقت وتنظيف الأشياء المحظورة.إذا حدث هذا الموقف لفترة طويلة ، فسيكون له تأثير قاتل على المكره.

ثانيًا ، يجب مراعاة نطاق التغذية للكسارة المطرقية العكسية ، حيث يجب أن يتم التغذية وفقًا للمتطلبات بدقة. سيكون للأنواع المختلفة من الرمل والحصى تأثيرات مختلفة على سرعة الكسارة ، لذلك يجب الانتباه إلى كفاءة إنتاج الكسارة.

لمزيد من المعلومات ، يرجى الاطلاع

https://turtlescompiegne.fr/

https://eliseharwal-graphotherapeute.fr/

https://enishi.fr/

https://miwa-spasportlunch.fr/

https://framingmymessage.nl/

https://tryskacimaterial.cz/

https://linstant-caennais.fr/

https://goooz.be/