1100 Aluminum Sheet Plate H12 14 H16 H18 H22 H24

Specifications of Aluminum Alloy Sheet:

1. Grade

1000 Series: 1050 1060 1070 1100 1200 1235 etc.

3000 Series: 3003 3004 3005 3102 3104 3105 3A21 etc.

5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc.

6000 Series: 6061 6063 6082 6A02 etc.

7000 Series: 7050 7075 7475 etc.

8000 Series: 8006 8011 8079 etc.

2. Thickness: 0.20mm-320mm

3. Width: 8mm-2400mm

4. Length: 1220 or per customer's request

5. Temper: all tempers, H1X, H2X, H3X, O, HXXX

6. Continuous casting and hot rolled both available

Manufacture of aluminum alloy plate:

Ingot + master alloy → smelting → holding furnace → continuous casting → cold rolling (intermediate annealing) → horizontal shearing → annealing → aluminum plate

Application of 4 x 8 aluminum sheet:

1. Planes, cars, trains

2. Building walls, ceilings, roofs, furniture cabinets, lighting panels

3. Ship board, solar reflector, corner guard, thermal insulation material

4. Beverage bottles, bottle caps, pull tabs, cosmetic casings and caps

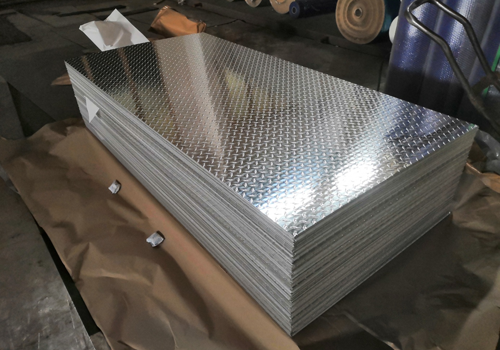

5. Aluminum tread/embossed sheet, quenched and pre-stretched sheet

6. PS substrate, CTP substrate, sign, nameplate

7. Electrical product shell, construction machinery sheet

8. Aluminum reefer containers and special containers, etc.

9. Rotation, automatic, etc.

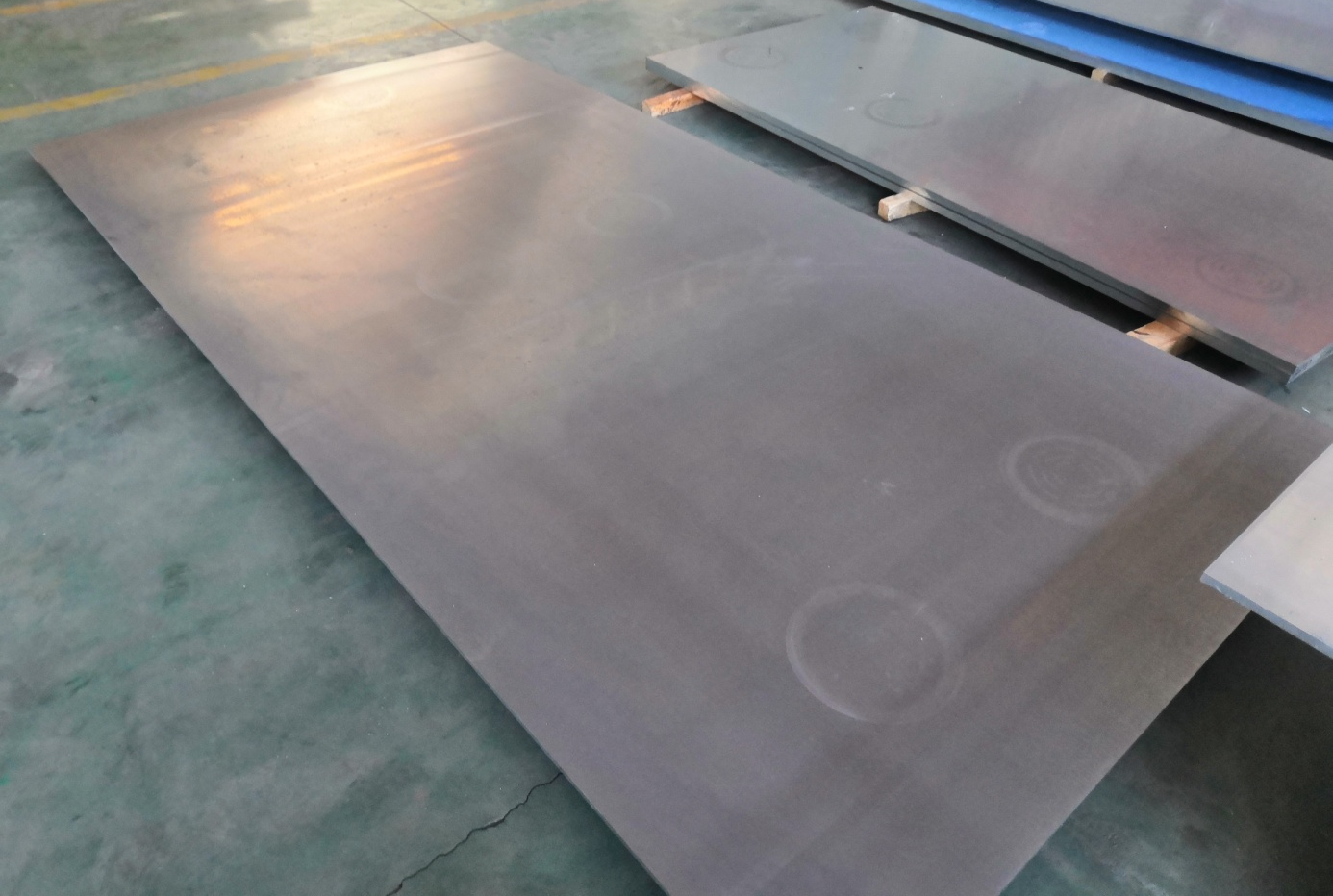

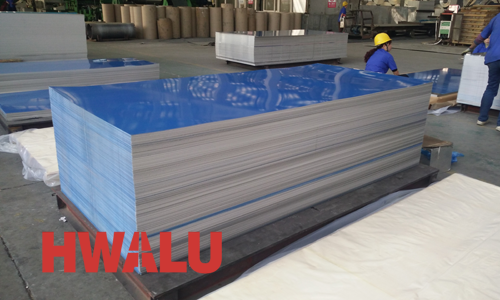

Factory Packing of Aluminum Sheets and Sheets

First, place the aluminum and aluminum sheets on the plank, aligning the edges.

Then, cover the steel plate with high-quality kraft paper

Finally, secure the kraft paper with packing tape, and a perfect package is created.

Alloy number of aluminum plate and aluminum plate:

1000 series: 1050 1060 1070 1100 1200 1235

3000 series: 3003 3004 3005 3105 3A21

5000 series: 5052 5083 5086 5754 5251

Specifications of aluminum plate and aluminum plate:

Thickness: 0.15mm-350mm

Width: 200mm-3000mm

For more technical information about aluminum sheet and 4 x 8 aluminum sheet products, please contact our friendly professional manager (augustao mei-aluminum ) for expert help to find the product that meets your needs.

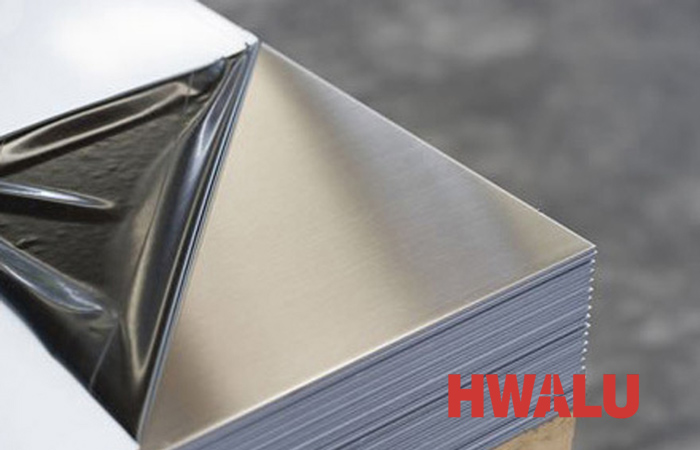

An important link in the processing of aluminum plate manufacturers

Aluminum products are processed by 4 x 8 aluminum sheet manufacturers through aluminum anodizing technology, which greatly improves wear resistance, corrosion resistance, light resistance, weather resistance and other properties, and can have a variety of beautiful and bright colors. It adapts to the requirements of the aesthetic feeling of the times, thereby greatly improving the application value of the aluminum plate.

Decorative aluminum sheet building profiles are the main materials for doors, windows and curtain wall structures and are widely used around the world. The aluminum alloy extruded profile (without surface treatment) has a single appearance and is easy to corrode in a humid atmosphere, so it is difficult to meet the requirements of high decoration and strong corrosion resistance of building materials.

In order to improve the decorative effect, enhance the corrosion resistance and prolong the service life, the aluminum plate usually needs to be surface treated. Therefore, aluminum anodizing surface treatment is an essential and extremely important process in the production of aluminum alloy profiles. The oxide film formed by anodization of aluminum alloy in -H2SO4 solution is white, transparent, high in porosity and good in chromaticity, especially suitable for aluminum oxidation processing.

An important link in the processing of aluminum plate manufacturers

Aluminum products are processed by aluminum sheet manufacturers through aluminum anodizing technology, which greatly improves wear resistance, corrosion resistance, light resistance, weather resistance and other properties, and can have a variety of beautiful and bright colors. It adapts to the requirements of the aesthetic feeling of the times, thereby greatly improving the application value of the aluminum plate.

Decorative 4 x 8 aluminum sheet building profiles are the main materials for doors, windows and curtain wall structures and are widely used around the world. The aluminum alloy extruded profile (without surface treatment) has a single appearance and is easy to corrode in a humid atmosphere, so it is difficult to meet the requirements of high decoration and strong corrosion resistance of building materials.

In order to improve the decorative effect, enhance the corrosion resistance and prolong the service life, the aluminum plate usually needs to be surface treated. Therefore, aluminum anodizing surface treatment is an essential and extremely important process in the production of aluminum alloy profiles. The oxide film formed by anodization of aluminum alloy in -H2SO4 solution is white, transparent, high in porosity and good in chromaticity, especially suitable for aluminum oxidation processing.

How Aluminum Sheets are used for making Aircraft

The aircraft industry is considered to be the most advanced industry, and the requirements for aircraft parts are very strict. 2024 and 7075 are the most commonly used aluminum alloys in aircraft aluminum sheets.

Manufacturers use high-strength alloys (primarily Alloy 7075) to strengthen Quality Alloy Aluminum Sheet structures and other aerospace equipment. Aluminum alloy 7075 has copper (1.6%), magnesium (2.5%), and zinc (5.6%) added for ultimate strength, but the copper in it makes it difficult to weld. On the other hand, it's anodized very nicely. 7075 has the best machinability, it produces a very nice finish.

As a typical aircraft aluminum sheet, 7075 aluminum sheet is a cold-worked forged alloy with high strength and high hardness, far superior to mild steel. 7075 aluminum sheet is one of the strongest commercial alloys with moderate corrosion resistance, good mechanical properties and anodic reaction. The fine grain makes the deep drilling performance better, the tool wear resistance is enhanced, the wire rolling is different from the weight, and the metal material with lower density requirements and higher hardness requirements is preferred. 7075 aluminum sheet is usually used to manufacture aircraft structures and other high-stress structural parts that require high strength and high corrosion resistance, such as aircraft upper and lower wings, stringers, partitions, etc. The 4 x 8 aluminum sheet for aircraft has good solid solubility after solution treatment, good heat treatment strengthening effect, high strength below 150°C, good low temperature strength, poor welding performance, and tendency to stress corrosion cracking. Double-stage aging can improve the resistance to stress corrosion cracking.

2024-T3 This is the most common high-strength aluminum alloy. It has high quality for use in airplanes. 2024-T3 aluminum sheet is considered an aircraft alloy because of its strength & it also has excellent fatigue resistance. Soldering is not recommended. Basically, 2024-T3 aluminum cladding panels are used for fuselage and wing skins, fairings, aircraft structures, and also for repair and restoration due to their shiny finish (2024-T3 aluminum cladding). It has an ultimate strength of 62,000 psi and a shear strength of 40,000 psi. For more information on other grades of aluminum sheet used on aircraft, please contact a China 2024 T3 sheet distributor.

Aluminum printing plate / aluminum plate for bottle cap

Aluminum printing plates are very popular as exterior signs. They are fastened to the wall or door and are an excellent solution for the era of direction or information signage. We can cut to any size, up to 10ft x 4ft, larger panels can be more than one piece. Aluminium composite panels are easy to screw in and the material is easy to drill because aluminium is very soft compared to steel. Anodized 4 x 8 aluminum sheet with porous surface finish and decorative surface texture. A protective coating applied to the material guarantees a one-year shelf life.

We also produce colored aluminum flakes for bottle caps and tinplates and have a full product development cycle such as design, plate making and printing. These aluminum printing plates and tinplates are very stylish and durable, guaranteeing a longer life and appearance of the product display.

Our 1060 Aluminum Sheet Plate is rolled to very fine tolerances to produce more closures per ton of stock and to allow for uninterrupted operation of high-speed, multi-chamber presses. Its strength, high formability, low earring and printable surface make it ideal for tamper-evident caps and vial closures.

1060 aluminum cans and caps, building materials, insulating materials, shoes and hats, eye protection, corner protection, automotive industry, deep processing, light industry, TV backplanes, street signs, PP caps, battery masks, etc.

At present, most of China's liquor, foreign wine, wine and beverages are mainly glass bottles, so many bottle caps are made of aluminum. According to experts, China's anti-theft bottle caps (aluminum Ropp caps) will grow at an annual rate of 10%. It is estimated that there will be about 15 billion anti-theft bottle caps in 2010, and the consumption of aluminum plates will be about 53,500 to 60,000 tons.

Anti-theft aluminum cover

Aluminum anti-theft caps are made of high-quality special aluminum alloy caps and are mainly used for the packaging of alcohol, beverages (including steam and steam) and medical and health care products, and can meet special requirements such as high temperature sterilization.

Most of the aluminum covers are processed on highly automated production lines, so the requirements for the strength, elongation, and dimensional deviation of aluminum alloy cover sheets are very strict, otherwise they will break or fold during processing. In order to ensure the convenience of printing after the bottle cap is formed, the surface is flat, and there is no required rolling marks, scratches and stains on the cover material, 8011-H14 aluminum alloy cover sheet and 3003-H16 aluminum alloy cover sheet in alloy state are used, and the material thickness of general specifications is used. 0.20mm ~ 0.23mm, width 449mm ~ 796mm. The production of aluminum alloy cap plate can use hot-rolled blanks or continuous casting and rolling blanks, the latter using cold rolling. At present, my country's anti-theft cover material production plants mostly use continuous casting and rolling billets, which are better than casting billets.

We are a leading aluminum product manufacturer in China. The products we produce include medicinal aluminum foil, packaging aluminum foil, aluminum foil, >aluminum sheet, aluminum strip, aluminum sheet and aluminum strip. Our long-term experience in this area perfectly guarantees product quality.

follow links:

https://oblq.online

https://dvtel.online

https://housta.online

https://acarapassion.site

https://pizzerialabellastoria.nl

http://villafortunaeventi.it

http://eetwinkeldegroenekever.nl

https://leo-sushi-pierre-benite.fr

http://villaegidiolocation.it

http://vinandro.it

https://restaurant-lajoliette.fr

https://lionsalu.github.io

https://hwalum.github.io

https://hw-matels.com

Illustrate The Use Of Aluminum Plate In Construction

In daily life, we can see 4 x 8 aluminum sheet everywhere, and aluminum plates have become an indispensable part of daily life.

Aluminum in particular is very active in the construction industry. Among them, single-layer aluminum plate is often used in construction projects due to its many advantages such as easy processing and various shapes. In aluminum curtain walls, single-layer aluminum is also used in large quantities, generally used as shielding walls or walls that are not too sunny.

It can treat the surface of curtain wall aluminum sheet in two ways, anodizing and electrostatic spraying. Anodizing has a single color, lacks variation, and uneven color distribution on the board, so it is not commonly used. Electrostatic spraying has various colors, is resistant to bumping and friction, and is not easy to wipe off. If it is only under the influence of ultraviolet rays for a long time, the color will be different.

Many of the current curtain walls are produced by aluminum plate manufacturers, because it is not only more compact and stronger, but also can be adjusted according to different needs, such as sound insulation and the like.

follow links:

https://pizzerialabellastoria.nl

http://villafortunaeventi.it

http://eetwinkeldegroenekever.nl

https://leo-sushi-pierre-benite.fr

https://oblq.online

https://dvtel.online

https://housta.online

https://lionsalu.github.io

https://hwalum.github.io

https://hw-matels.com

- 未命名 -

What are the uses of aluminium sheet in industry?

There are many industries uses 4 x 8 aluminum sheet metal fabrication nowadays. Aluminum is often used in aerospace, spacecraft fuel tanks, automobile bodies, home appliances and cookware, etc. Below are the most common applications of aluminium you never would have quite expected:

Precision Tubing in motor Air Conditioning, Refrigerators, Vehicles etc:

Strong heat transfer applications allow it to be used extensively for the automotive, AC and solar market industries, as well as for carrying liquids or gases

Packaging:

Aluminium sheets are completely recyclable, which saves a lot of energy. It is used to package food and drinks, such as bottle caps, containers, cans and medication packaging

Rolled Aluminium Products:

Use of aluminium is more common everyday use, by its more informal title tin foil is produced through the metalworking process of 'rolling', whereby sheet ingots are cast from molten billet aluminium, then re-rolled on sheet and foil rolling mills to the desired thickness

Automotive and Construction:

As people start to recognize the importance fuel efficiency and reducing CO2 emissions, more and more automotive manufacturers have begun using more aluminium in their designs. Aluminium is pretty much necessary in construction work! From skylights to bridges and ladders to railings, whether implemented as rods, doors or wiring etc

China's reliable Aluminum Sheet manufacturers and suppliers

The production capacity of huawei is 1-8 series aluminum sheet,aluminum plate,aluminum circles/disk,aluminum strip,aluminum coil, aluminum foil, aluminum tread plate and so on. huawei is dedicated to provide you quality products with competitive price and quick aftersale services.

follow links:

https://pizzerialabellastoria.nl

http://villafortunaeventi.it

http://eetwinkeldegroenekever.nl

https://leo-sushi-pierre-benite.fr

https://oblq.online

https://dvtel.online

https://housta.online

https://lionsalu.github.io

https://hwalum.github.io

https://hw-matels.com