Aluminum alloy plate 6061 t6 | Huawei Aluminum

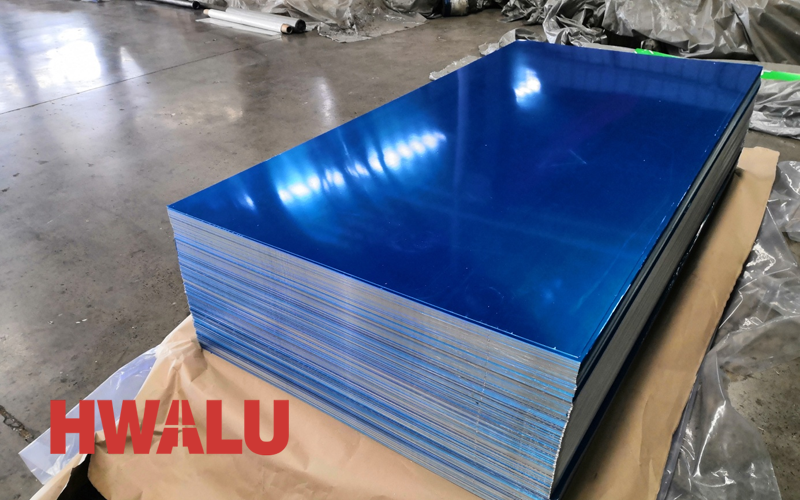

Aluminum alloy plate 6061 t6 is usually used in the fields of automated mechanical parts, finishing and mold making. Through mechanical processing, 6061 aluminum alloy plate can be used to manufacture mobile phone card slots, mobile phone cases, molds, auto parts, mask machines, trolley cases, door panels, etc. 6061 4 x 8 aluminum sheet has strong decorative surface treatment, can be anodized and colored, and can be continuously punched at high speed, which is convenient for direct processing and forming.

Huawei Aluminum is a professional aluminum alloy sheet 6061 t6 manufacturer with multiple advantages.

1. 25 years of rich experience.

As a long-established aluminum sheet manufacturer, Huawei Aluminum has 25 years of production experience, rich and mature, high-level processing technology, and exquisite craftsmanship, which can provide you with excellent quality and high-quality products.

2. Advanced hardware equipment.

Huawei has 1+1, 1+4 hot rolling production lines and imported six-high cold rolling mill equipment. Huawei Aluminum can produce ultra-wide and ultra-thick 6061 aluminum alloy sheets, which eliminates internal stress and does not deform during cutting.

3. Comprehensive services.

Huawei Aluminium&# 8217;s has a one-stop service attitude of pre-sale, in-sale and after-sale services, enthusiastic service, preferential quotation, and solves problems for users.

The price of 6061 T6 Aluminum Sheet 6061 t6 is not only related to the price of raw material aluminum ingots, but also related to factors such as product thickness, width, and condition. 6061 aluminum plate, as a kind of aluminum alloy with a wide range of uses and high demand, has more than one supplier. Due to the difference in the selection of raw materials, the manufacturing process and the quality of the product, the quotations are also different.

What should we do to make the pattern of the aluminum plate smooth?

In some public places or mechanical products, we can see aluminum sheets. They can play a decorative role and can also play a certain anti-slip effect, you must be very welcome. We also found that after the patterned aluminum plate is used for a long time, the pattern on the surface of the 4 x 8 aluminum sheet will become smooth, so that the effect will not be very good whether it is decoration or anti-skid. If it is at this time, then we need to replace it with a new one. the patterned aluminum plate.

You have to ask, if the mechanical pattern aluminum floor above is bald, then I need to remake the whole machine, what should I do with my work? If the pattern on the home decor is worn off, does that mean all the decor has to be removed to get the whole job done? That's too much trouble.

There is no need to be so troublesome. If the aluminum alloy pattern on the machine is smooth, then we can ask special maintenance personnel to ask them to find which layer of the new aluminum alloy 5052 pattern should be on the original layer, and that's it. If it is a smooth embellishment, we can also use this method to repair it.

In fact, diamond plate aluminum manufacturers remind you that if this pattern is not needed, then we can ignore it completely, because even aluminum plate, a new decoration, if we can reinvent it again, then there will be Effect.

6061 T6 aluminum alloy sheet

6061 t6 aluminum alloy plate has three different common heat treatment states: O, T4 and t6. The difference between the state of 6061 o aluminum sheet T6 and T651 is that in general, the internal stress of T6 will be relatively large, and the processing will be deformed. 6061 T651 should be a more suitable processing state, which is stretched on the basis of the T6 state to eliminate internal stress. The hardness of 6061 aluminum alloy plate has a lot to do with its composition. The higher the magnesium content, the better the hardness.

The main alloying elements of 6061 t6 aluminum alloy sheet are magnesium and silicon, and form Mg2Si phase. If it contains a certain amount of manganese and chromium, it can neutralize the adverse effects of iron. Small amounts of copper or zinc are sometimes added to increase the strength of the alloy without significantly reducing its corrosion resistance. There is a small amount of conductive material to counteract the detrimental effects of titanium and iron on conductivity. The zirconium or titanium in the 6061 aluminum plate can refine the grains and control the recrystallization structure. To improve machinability, lead and bismuth may be added. Mg2Si is solid-dissolved in aluminum, which makes the alloy have artificial age hardening function.

6061 t6 aluminum alloy sheet has good processing performance, good corrosion resistance, high toughness, easy coloring after processing, and good oxidation effect. The main uses of 4 x 8 aluminum sheet are: widely used in various industrial structural parts that require a certain strength and high corrosion resistance, such as the manufacture of trucks, tower buildings, ships, trams and railway vehicles. 6061 Aluminum Alloy Material & # 8217; Proprietary chemistry, casting and production techniques are the stability and consistency of the material. High stability and consistency, reducing deformation and movement during sawing and machining.

4 x 8 price of aluminum plate

4 x 8 aluminum sheets are the best-selling alloy aluminum sheets on the market, with alloys ranging from 1000 series to 8000 series. Therefore, the price of the national standard 4 x 8 aluminum sheet on the market must be of concern to everyone. Huawei Aluminum will analyze the market price of aluminum sheets for you.

1. Specifications and quality are fundamental

Specifications and quality affect the price of 4 x 8 aluminum plate is ultimately reflected in the specification and quality of the alloy. The aluminum plate market tends to be saturated. Under the competition, the price of 5052 aluminum plate is lower than that of 6061 aluminum plate and 6063 aluminum plate, while 6061 aluminum plate is a hot-selling product in the market, with strict process requirements, relatively few manufacturers, and the price is naturally more expensive. There are many 5052 Aluminum Sheet manufacturers, and the market is relatively saturated, so the price of 5052 aluminum plate is relatively cheap.

2. 4x8 aluminum sheet manufacturer is the key

At present, there are many 8x4 aluminum plate manufacturers in China, and there are hundreds of aluminum plate manufacturers in China alone. Among these manufacturers, the scale, nature and strength of the manufacturers are different, and the quotations for aluminum sheets are naturally different. It is recommended that consumers buy products from large, direct-selling, and powerful manufacturers, because these manufacturers have advanced equipment, high technology, better quality, and more reasonable prices.

3. Direct cost factors

The level of cost will directly affect the price level of 48 aluminum sheets. In the production process, it is inevitable to spend a certain amount of investment in manpower, material resources and technology. The higher the cost of 4x8 aluminum plate manufacturers in this regard, the higher the price.

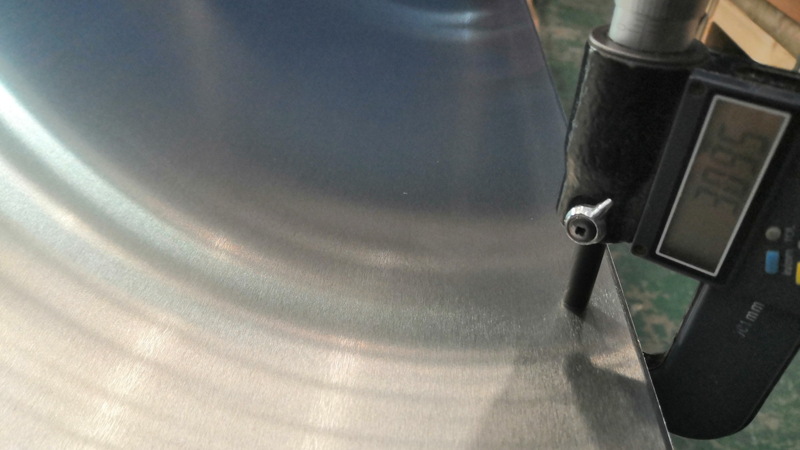

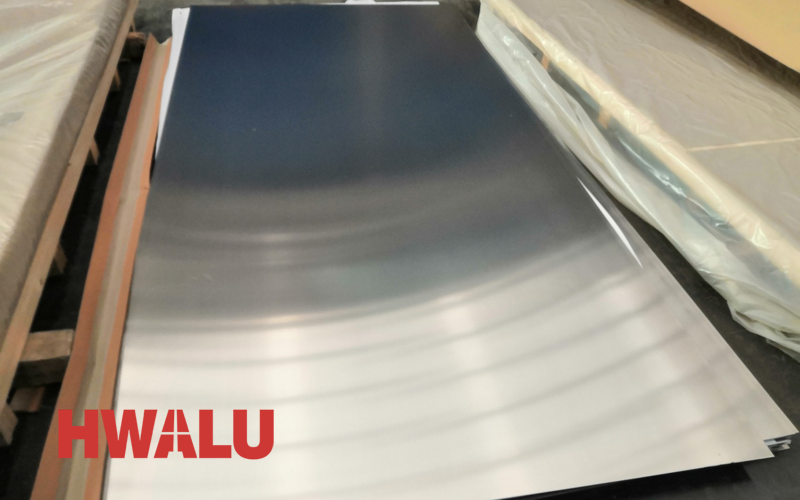

High quality hot rolled steel sheet

Hot-rolled sheet, also known as hot-rolled sheet or hot-rolled steel plate, refers to an aluminum sheet product processed by a hot rolling mill. Usually, hot-rolled aluminum sheets are made from 4 x 8 aluminum sheet with a thickness of 400-500 mm that are processed multiple times by a hot-rolling mill. Due to the higher pressure during processing, the internal structure is more uniform and the grain size is better. The microstructure of the hot-rolled aluminum sheet is more uniform and dense. After anodizing, the surface texture of the hot-rolled aluminum plate is consistent, without ripples and color difference.

In the process of hot-rolled sheet processing, it is necessary to reasonably control the metallographic structure, mechanical properties, surface quality and geometric size and shape of the hot-rolled aluminum sheet to meet the quality requirements of subsequent processing and final products. In the hot rolling process of aluminum and aluminum alloys, the change of microstructure is a very complicated process. First, the grains of the material are deformed under the action of the strong rolling force, the as-cast grains are flattened, and the grains of the material are flattened along the rolling direction, while being elongated and strain hardened, and then dynamic recovery and dynamic regeneration may occur. crystallization.

Hot-rolled sheet products are generally divided into two categories, one is hot-rolled thick aluminum plate, and the other is hot-rolled aluminum coil. Hot-rolled thick aluminum plate refers to an aluminum alloy plate with a thickness of not less than 6.0 mm. The main varieties are hot-rolled plate (H112), annealed plate (O), quenched or quenched pre-stretched plate, etc. Hot rolled 1/8 aluminum sheet are usually used in hot rolling mills. It is produced by the block method, and its typical process is: ingot (homogenization) milling, edge rolling, heating, hot rolling, shearing, interruption, straightening.

The difference between 3003 and 5002 aluminum plate

3003 and 5052 aluminum plates are the most common alloy 4 x 8 aluminum sheet, but many people do not know the difference between the two. Take 3003 h24, aluminum and 5052 h24 aluminum plates as examples to explain this knowledge.

1. From the chemical composition of 3003 aluminum, it is an aluminum-manganese alloy, and the main alloying element is manganese. 5052 aluminum plate is an aluminum-magnesium alloy, and the main alloying element is magnesium. The aluminum content of 3003 aluminum is slightly higher than that of 5052 aluminum.

2. From the point of view of mechanical properties, the tensile strength of 3003H24 aluminum is 145-195Rm/MPa, while the tensile strength of 5052H24 aluminum is as high as 230-280Rm/MPa, which is much higher than that of 3003H24 aluminum; the tensile strength of 3003H24 aluminum plate is 115Rm /MPa, the tensile strength of 5052H24 aluminum plate is 150Rm/MPa. Therefore, the performance of 5052 aluminum is significantly better than that of 3003 aluminum.

3. The commonly used specifications of 3003 aluminum plate are mainly thin plates, and the application of thick plates is seldom; and 5052 aluminum plates are also widely used in addition to thin plates.

4. In terms of scope, 3003 1/8 aluminum sheet is mainly used in humid environments, such as product packaging, refrigerators, air conditioners, refrigerators, ventilation ducts, etc. The 5052 aluminum plate is often used in electrical enclosures, transportation vehicles, pressure vessels, etc., and is a common material for the manufacture of automobiles, aircraft fuel tanks, and fuel pipes.

The difference between the conductivity of copper sheet and aluminum sheet

What is the difference between 4 x 8 aluminum sheet and copper sheet, and what is the difference in electrical conductivity?

Aluminium article from: Materials and copper are very common in our daily lives.

Aluminum ingots are aluminum products obtained from rolls, which may need to be cut into aluminum of desired widths through different slitting. Aluminum strips are sold according to different uses, and are an important raw material in industry. Aluminum has many uses, such as aluminum-plastic composite pipes, cables, optical cables, transformers, heaters, shutters, etc. Specific uses are: aluminum transformers, transformers, aluminum foil, high-frequency welding hollow aluminum with aluminum fins, aluminum radiators with aluminum, aluminum cables with aluminum, aluminum punching with aluminum, aluminum trim with aluminum, etc. The main aluminum processing equipment is the sub-unit, which can be processed into the required length and width according to the needs. Of course, slitting equipment is common, and can be divided into eight series according to the alloying elements contained in aluminum

As the 1/8 aluminum sheet manufacturer can see from the physical properties of the metal conductive sheet, the electrical conductivity of aluminum is only lower than that of copper, so aluminum strips are becoming an international trend to replace copper strips, so that the raw materials of electronic products are no longer purely dependent on copper strips.

Several common applications of aluminum sheets are introduced

3003 aluminum plate: mainly used for processing parts that require good formability, high corrosion resistance or good weldability. ;

1060 aluminum: cold rods are mainly used in occasions where corrosion resistance and formability are relatively high, but the strength requirements for components are low, such as chemical equipment, marine equipment, railway tankers, conductive materials, etc.;

Alloy aluminum sheets, <a href="https://hw-matels.com/size-aluminum/4x8-metal-aluminum-sheet.php">4 x 8 aluminum sheet</a> for sale, sheets, drawn tubes, extruded tubes, house partitions, roofs, pipes, etc. ;

5052 aluminum plate, sheet, plate, foil, drawing tube, cold-rolled plate, used in the manufacture of aircraft fuel tanks, oil pipes, transportation vehicles, sheet metal parts of ships, instruments, rivet wires for lamp brackets, etc. ;

6061 Aluminum: Aluminum sheet metal, thick material, drawn tube, commonly used in the manufacture of trucks, tower buildings, ships, trams, railway vehicles, furniture, etc. Tubes, rods, profiles.

The difference between aluminum sheet T5 and T6

The forming temperature of the 4 x 8 aluminum sheet extrusion profile is 460 ~ 460 degrees, and the temperature after quenching is generally required to be 200 degrees. Through high temperature extrusion, the solution heat treatment (quenching) is followed by air cooling in artificial aging state (T5); through high temperature cooling extrusion process, water cooling in artificial aging state is then performed (T6).

Aluminum quenching suddenly drops from high temperature to low temperature quenching. For example, steel knife blades should be quenched in water, only hard and sharp. Aluminum quenching has both water-cooled quenching and air-cooled quenching. The 6063 aluminum building is air-cooled and quenched. The quenched aluminum is aged in an aging furnace for a certain period of time, and the internal crystals of the aluminum are rearranged, and the mechanical strength is significantly improved.

Air cooling, T5 is forced extrusion, T6 is water cooling, and the hardness increases after water quenching. However, the diamond-shaped aluminum plate needs to be bent, try not to reach the T6 state,

Some people think that the difference between the 1/8 aluminum sheet T5 and T6 is only part of the difference in cooling speed, not the air cooling water. The difference between the cooling rates of air cooling is large enough to achieve the effect of T6, on the contrary, the cooling rate of water cooling is not large enough, and it can only achieve the effect of T5.

In fact, the T6 state can be quenched online (water or air) or offline (quenched with a quenching furnace), but it depends on the customer's requirements and the product specifications of the aluminum foil manufacturer.

New application areas of aluminum sheets

It is understood that the key areas for expanding the application of ground 4 x 8 aluminum sheet include: transportation, building structures, and electric power. In addition, it also includes aluminum trays, aluminum alloy bridge flood control facilities, aluminum alloys, aluminum foil packaging products and other fields.

Transport sector:

Scope: extended aluminum trailers, convertible aluminum-coal trucks, high-precision aluminum sheet applications for automobiles.

The artistic structure of aluminum plate:

Scope: Expansion Aluminum Alloy Building Formwork, Aluminum Enclosure Application

(1) Expand the application of aluminum alloy building formwork

The amount of aluminum used in domestic formwork continues to grow, and domestic companies also supply aluminum formwork and formwork aluminum to Brazil, India, Venezuela and other countries, as well as Hong Kong and Macao, which will also drive domestic aluminum consumption.

(2) Expand the application of aluminum casing

In domestic civil buildings, large-scale infrastructure projects, especially large-span and complex-shaped projects, such as airport terminals, exhibition centers, stadiums and other public buildings, have widely used 3003 Aluminum Sheet for the roofs and walls. However, in industrial buildings, the steel structure sheet metal enclosure system accounts for about 70% of the total building, and aluminum is less used.

electric field:

my country's copper resources are in short supply and need to be imported in large quantities. The proportion of copper in the field of electricity consumption accounts for more than 40% of the total consumption. my country has formed a strong industrial base 5052 aluminum plate resources, replacing the insufficiently protected copper resources, to a certain extent, it can reduce the external dependence of my country's copper resources and enhance the resource security capability.