Aluminum alloy plate 6061 t6 is usually used in the fields of automated mechanical parts, finishing and mold making. Through mechanical processing, 6061 aluminum alloy plate can be used to manufacture mobile phone card slots, mobile phone cases, molds, auto parts, mask machines, trolley cases, door panels, etc. 6061

4 x 8 aluminum sheet has strong decorative surface treatment, can be anodized and colored, and can be continuously punched at high speed, which is convenient for direct processing and forming.

Huawei Aluminum is a professional aluminum alloy sheet 6061 t6 manufacturer with multiple advantages.

1. 25 years of rich experience.

As a long-established aluminum sheet manufacturer, Huawei Aluminum has 25 years of production experience, rich and mature, high-level processing technology, and exquisite craftsmanship, which can provide you with excellent quality and high-quality products.

2. Advanced hardware equipment.

Huawei has 1+1, 1+4 hot rolling production lines and imported six-high cold rolling mill equipment. Huawei Aluminum can produce ultra-wide and ultra-thick 6061 aluminum alloy sheets, which eliminates internal stress and does not deform during cutting.

3. Comprehensive services.

Huawei Aluminium&# 8217;s has a one-stop service attitude of pre-sale, in-sale and after-sale services, enthusiastic service, preferential quotation, and solves problems for users.

The price of

6061 T6 Aluminum Sheet 6061 t6 is not only related to the price of raw material aluminum ingots, but also related to factors such as product thickness, width, and condition. 6061 aluminum plate, as a kind of aluminum alloy with a wide range of uses and high demand, has more than one supplier. Due to the difference in the selection of raw materials, the manufacturing process and the quality of the product, the quotations are also different.

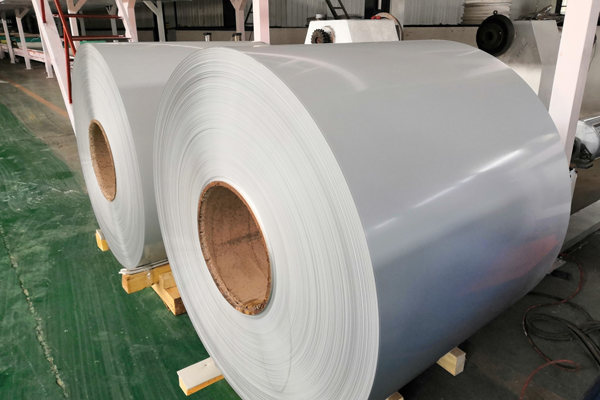

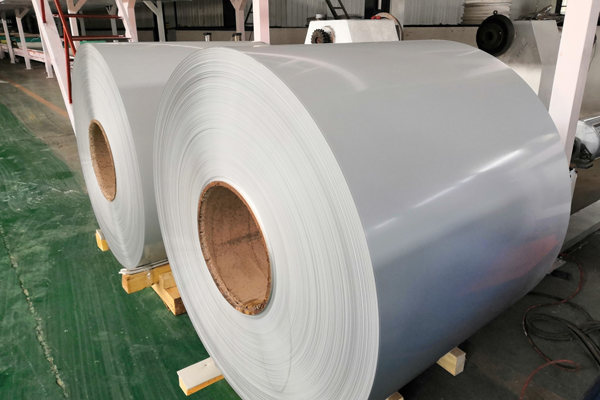

PVDF fluorocarbon coatings for

3003 Aluminum Sheet Plate are the darling of the existing architectural coatings market. It can be said that it is recognized as an organic coating with a strong protective effect. Aluminum-magnesium-manganese 3003 aluminum is an alloy material composed of three elements: aluminum, magnesium and manganese. It has the advantages of high strength, good toughness, corrosion resistance and aging resistance. It has moderate structural strength, weather resistance, pollution resistance, easy bending and welding, etc. Unbeatable price/performance ratio, considered a roofing and façade material with a service life of over 50 years.

Aluminum-magnesium-manganese 3003 coil with fluorocarbon coating for metal structure can keep it undamaged for decades and always maintain beautiful color. So far, fluorocarbon pre-coated aluminum-magnesium-manganese panels have been used in construction in various fields around the world for more than 30 years and have maintained their excellent performance. Color coated aluminum sheet 3003 typically has a thickness of 0.024mm-4.0mm and a width of 1700mm or less. In addition to PVDF coating, there is also PE coating, which is low-cost and can be used for interior decoration. The colors of pre-painted aluminum are green, blue, yellow, white, black, etc. PVDF is polyvinylidene fluoride. Due to the electronegativity of the fluorine atom, it forms a very stable carbon-fluorine bond. Coupled with its unique molecular symmetry, PVDF has extraordinary stability and unique resistance to UV degradation. as well as excellent insulating and mechanical properties. Since the application of fluorocarbon-coated aluminum-magnesium-manganese sheets, the pretreatment of aluminum-magnesium-manganese sheets has gradually developed in a simple and efficient direction.

Before the anti-corrosion construction of

5005 H34 Aluminum Coil, some more economical and practical pretreatment measures must be taken for later use. So how does the aluminum-magnesium-manganese color-coated plate anti-corrosion? In the past, the most common pretreatment method was to treat the surface of the aluminum-magnesium-manganese coated coil with an acid or alkali solution to dissolve the oxide layer, rust and oil stains on the surface, and then carry out the next step of anti-corrosion treatment.

Aluminum 5-stripe pedals are often called anti-skid 4x8 Aluminum Diamond Plate, and their surface has 5-stripe patterns to ensure anti-slip performance. The 5 bar aluminium pedals have good slip resistance and are also more wear-resistant. It can be divided into five large aluminum checker plates and small five aluminum checker plates, which are commonly used products in anti-skid aluminum checker plates.

At present, the commonly used aluminum 5-rib pedals on the market are: 1060 five-rib aluminum pedal, 3003 five-rib aluminum pedal, 5052 five-rib aluminum pedal, 5754 five-rib aluminum pedal, 6061 five-rib aluminum pedal, 6063 five-rib aluminum pedal, 6082 five-rib aluminum pedal Aluminium grating etc. The invention has novel structure, good anti-skid effect, light weight and good durability. The mass per square meter is about 7kg, and its tensile strength is 200N square millimeter. The aluminum pedal has high elongation, and the relative elongation is higher than 10%. It can withstand high bending without breaking and has good toughness. Typical uses are to make non-slip bases, non-slip step ladders, or to be used in packaging, construction, curtain walls, etc. On the stairs, we often see the existence of anti-skid aluminum plates.

Compared with similar products, Five-bar tread aluminum sheets have obvious advantages in hardness and tensile strength. In addition, the five-bar aluminum pedals are also highly resistant to corrosion and rust. It is mainly used in work platforms, ships, vehicles, buildings, etc. because of its remarkable effect in aesthetics, anti-rust and anti-skid.

Aluminum alloy sheet refers to aluminum alloy products other than pure aluminum series. The aluminum alloy plate series includes 2000 series, 3000 series, 5000 series, 6000 series, 7000 series and 8000 series. This is probably to popularize the internal chemical composition of the alloy

4x8 Aluminum Sheet, so that everyone can understand the knowledge of the alloy aluminum plate.

Let's start with the 2000 series. This series of aluminum alloy plates have high internal copper content and can be heat treated. It is a hard aluminum alloy commonly used in various mold and machinery industries. 3000 series alloy aluminum plate is aluminum-manganese alloy, which is a relatively cheap alloy. In particular, the 3003 aluminum plate is a relatively low-priced product in the alloy aluminum plate. The internal alloy content of manganese alloys is higher than the price. The 5000 series aluminum plate is also an anti-rust aluminum, but the price is higher than that of the 3000 series. The alloy hardness of the 5000 series aluminum plate is higher and the rust resistance is better. 6000 series alloys belong to aluminum magnesium silicon alloys. It contains a certain amount of magnesium alloy and silicon alloy. It has good welding properties and is widely used in brazing. In particular, this series of alloys can be quenched to T6 temper.

Huawei Aluminum is a manufacturer of aluminum alloy sheet products. Each product undergoes strict quality inspection before leaving the factory. In addition, the specifications of the

0.75 aluminum sheet are complete. We can provide tailor-made services according to the actual production needs of users. The price of buying aluminum sheets from Huawei is very affordable. We are a large direct selling manufacturer and a strong listed company. Not only the product quality is guaranteed, but the price is also lower than other manufacturers in the same industry.

Coated and embossed

5052 Aluminum Coil is a new type of material that improves mechanical properties and structural strength through an embossing process. At the same strength, it effectively reduces the thickness of the coated aluminum coil, at the same time. Embossed coated aluminum has the excellent decorative and functional properties of both embossed and coated aluminum. Energy saving and consumption reduction can be achieved by changing the structure of coated aluminum products, while maintaining or even improving the original decorative properties of metal materials. For some electrical and architectural fields that require a low-cost trend, embossed coated aluminum sheets will undoubtedly be a good choice.

Coated embossed aluminum coils are mainly made of 3004 and

3003 Alloy Metal Aluminum Coil, with a thickness of 0.18-1.5 mm and a width of 580-1850 mm. Embossed color-coated aluminum coil is a fashionable new high-end decorative material, especially suitable for the decoration of high-end home appliances, such as refrigerator doors. Side panels, water heater shells, TV back panels, washing machine panels, etc. The stucco embossed color-coated aluminum coil products have: the texture is clear and uniform. Temperature resistance, weather resistance, strong fire resistance, dirt resistance and easy cleaning.

Coated embossed aluminum coils for refrigerator side panels account for about 70% of all color-coated aluminum panels for home appliances, and most of them require embossing. In the past, after customers ordered color-coated aluminum coils from the factory, they had to find another processing factory for embossing, which not only brought trouble to customers, but also lost part of the high-end market, hindering the upgrading of product structure. The most commonly used 0.4* 1290 mm brown-grey coated board in refrigerator side panels with an orange peel embossed pattern. This product solves the long-term troubles since the cooperation with customers, and lays a solid foundation for the increase of high-end color-coated boards. At the same time, the improvement of deep processing level will also increase the economic added value of color-coated household appliances, and promote the company's healthy development.

1060, 3003, 5052, 5083 grades of aluminum 5-bar pedals have beautiful appearance, strong metallic color and obvious decorative effect. Mainly used for anti-slip on the ground or work platform. Currently widely used in foot pedals. At the same time, it is widely used in the anti-skid of carriages and ship warehouses. The thickness of the five anti-skid 4x8 aluminum sheet is generally 1-10 mm, the width is 1000-1500 mm, and the length is 2000-3000 mm. The 1060 aluminum 5-bar pedal belongs to the 1000 series pure aluminum grade, so the price is low. The application is the public environment. 3003 aluminum pedals 5 strips are common products in the aluminum-manganese alloy series. The 3003 aluminum pedals have excellent rust resistance due to the manganese alloying element. It is often used in humid environments such as outer packaging, mechanical parts and freezers. According to the order of metal thermal conductivity, corrosion resistance and production cost, the inner tank of the freezer uses 5 bar aluminum pedals instead of other metals. On the premise of ensuring its good thermal conductivity, the cost is reduced as much as possible, and corrosion-resistant materials are used. For machining, aluminum is the best choice. According to the surface pattern and surface finish, aluminum 5-bar pedals are divided into large 5-bar pattern aluminum pedals, large 5-bar mirror aluminum pedals, small 5-bar 4x8 Aluminum Sheet and small 5-bar mirror aluminum pedals. The main function of the 5 bar aluminum tread plate is to prevent slipping, and it is often used in contact belts such as cold storage projects, automobiles, buses, and trains.

PVDF aluminum sheets, also known as fluorocarbon aluminum sheets and PVDF aluminum sheets, are the most common color-coated aluminum products on the market. PVDF

0.75 Aluminum Plate has strong thermal stability, relatively wear resistance, impact resistance, UV resistance, radiation resistance, gloss and color retention, chemical corrosion resistance, and stain resistance. The aluminum grades of PVDF-coated aluminum are 3003 and 3004, and the 3003 aluminum alloy containing manganese and magnesium elements is usually used. The thickness of pvdf color coated aluminum sheet is 0.18-1.5mm and the width is 580-1850mm, please note that the PVDF thickness of Huawei aluminum is more than 25 microns, which has better performance and longer life.

The fluorocarbon coating of pvdf aluminum plate has excellent corrosion resistance and weather resistance, can resist acid rain, salt spray and various air pollutants, has excellent cold resistance and heat resistance, can resist strong ultraviolet radiation, and can maintain long-term Fading, no chalking, long lasting. The whole process of pvdf color-coated aluminum sheet production equipment is automated, and the coating quality fully reaches the level of imported

Color Aluminum Sheet Plate, which conforms to national standards and has passed a number of professional inspections.

The pvdf aluminum plate 3003 provided by Huawei Aluminum has the following advantages:

1. Zero color difference, the paint is directly customized and adjusted by the manufacturer.

2. The entire coating film and surface are free of particles and pores.

3. Environmental protection paint, no pollution.

4. Smooth surface and high flatness.

5, strong weather resistance, can adapt to different environments.

6. Ultra-low loss, high utilization rate, saving project costs.

7. There will be no flow marks caused by too thick coating during spraying.

8. Good self-cleaning, surface dust and other pollutants can be easily washed away in the rain.

In some public places or mechanical products, we can see aluminum sheets. They can play a decorative role and can also play a certain anti-slip effect, you must be very welcome. We also found that after the patterned aluminum plate is used for a long time, the pattern on the surface of the

4 x 8 aluminum sheet will become smooth, so that the effect will not be very good whether it is decoration or anti-skid. If it is at this time, then we need to replace it with a new one. the patterned aluminum plate.

You have to ask, if the mechanical pattern aluminum floor above is bald, then I need to remake the whole machine, what should I do with my work? If the pattern on the home decor is worn off, does that mean all the decor has to be removed to get the whole job done? That's too much trouble.

There is no need to be so troublesome. If the aluminum alloy pattern on the machine is smooth, then we can ask special maintenance personnel to ask them to find which layer of the new aluminum alloy 5052 pattern should be on the original layer, and that's it. If it is a smooth embellishment, we can also use this method to repair it.

In fact, diamond plate aluminum manufacturers remind you that if this pattern is not needed, then we can ignore it completely, because even aluminum plate, a new decoration, if we can reinvent it again, then there will be Effect.

Huawei is a professional 4x8 aluminum sheet supplier in China, producing high-quality, low-cost, and fast-producing

0.75 Aluminum Plate. As an aluminum sheet production factory, Huawei can produce aluminum sheets of various specifications, with thicknesses from 0.12mm to 500mm and widths from 500mm to 2600mm. 4x8 aluminum plate products are widely used in ship plates, oil tankers, automobiles, electronic products, construction and many other aspects.

The detailed specifications of Huawei 4x8 aluminum plate are as follows:

Alloys: 1070, 1060, 1050, 1100, 2024, 3003, 3004, 3105, 5052, 5083, 5086, 5754, 6061, 6082, 8011, etc.

Temperament: H18, H26, H16, H14, H24, H22, O, etc.

Thickness: 0.12~500mm

Width: 500~2600mm

Length: 800~8000mm

Application areas: The main areas are sign turntables, building anti-corrosion engineering, automobile manufacturing, refrigeration, electrical manufacturing and pharmaceutical advertising and other industries.

4x8 aluminum sheet is a general specification for aluminum sheet metal products. The aluminum sheet 4x8 produced by Huawei is of high quality, smooth in appearance, clean in surface, low in price, and excellent in sales and after-sales service. When we buy

4x8 aluminum sheet, the strength of aluminum plate manufacturers is very important. Select well-known aluminum plate manufacturers, strong strength, more mature processing technology, advanced product equipment, and more secure products. Huawei Aluminum has 25 years of production and processing experience, with an annual output of 200,000 tons, strong strength, and guaranteed quality of 4x8 aluminum plate products.

The aluminum plate of Huawei 4x8 aluminum sheet is very reasonably priced, which can save your purchase cost under the condition of ensuring the quality. The 4x8 aluminum plate produced by Huawei Aluminum Factory has high precision, and the vertical and horizontal parallel error is 2mm. According to the needs of different customers, 4x8 aluminum plates can be placed in two directions on the plane with very high precision. The vertical and horizontal parallelism error is ±2mm, the vertical and horizontal vertical error is ≤ 0.1mm/200mm, and the surface roughness of the cutting section is RA ≤ 25 (when the feed speed is 1 m/min), which ensures the accuracy of customer products in production. Due to the different processes adopted by various enterprises in the processing of 1/8 aluminum sheet, for example, large enterprises choose aluminum ingots as the raw material for the production of aluminum plates 4x8, while some small enterprises use recycled aluminum as the raw materials for the production of aluminum plates, which has a certain impact on the price of aluminum plates 4x8. The price of recycled aluminum is much lower than the price of aluminum ingots, and of course the quality of aluminum flakes is better than that of recycled aluminum. So the processing technology and materials affect the price of the aluminum sheet 4x8. It can be seen from the above points that the international aluminum market price fluctuates greatly, and the factors of processing technology and raw materials also have a great impact on the price of aluminum sheet 4x8. Therefore, it is recommended that aluminum plate demand companies not blindly covet price and give up quality, especially for aluminum plates produced from recycled aluminum, due to the increase in impurity content, it has a great impact on quality.