What is the use of 2mm thick aluminum plate

Different applications have different requirements for the thickness of aluminum sheets sometimes. Common aluminum plate thicknesses are 1, 2, 3, 4, 5, 6, 8, 10, 15 mm, etc. , especially the 1/8 aluminum sheet. For the same alloy, 2mm aluminum sheets are also cheaper. Let's see its common usage.

road sign

Circular and triangular traffic sign materials generally use 1.2 mm, 1.5 mm and 2 mm aluminum plates. For large road signs and highway signs, aluminum sheets with a thickness of 2.5 or 3 mm are required. 1060 or 3003 aluminum sheets are common choices.

Aluminum solid plate

The aluminum solid board can choose different thicknesses according to different architectural decoration requirements. The conventional thickness is 1.5mm, 2.0mm, 2.5mm, 3.0mm, the thickness of aluminum plate for outdoor building decoration is generally 2.5mm, 3mm; the thickness of 2.0mm can be selected for indoor decoration; the thinnest 1.5mm can be selected for indoor ceiling decoration.

shipbuilding

Marine aluminum plate generally refers to aluminum-magnesium alloy. At present, the commonly used aluminum plate is 5083 aluminum plate, such as 5083H116 aluminum plate and 5083 aluminum sheet. Common thicknesses are 2 mm, 3 mm, 4 mm, 5 mm, 6 mm, 8 mm, 10 mm, etc.

aluminum body

On the premise of ensuring the rigidity, strength and safety performance of automobiles, by changing the materials of automobile structures and parts, lightweighting helps to improve the fuel efficiency of automobiles and reduce pollutant emissions. 5052 aluminum sheets with a thickness of 2 mm are usually used for the front and rear panels of automobiles.

aluminum pedal

Aluminum pedals reduce the risk of slipping. It is commonly used in stairs, walks, walkways, ramps, treads for ambulances and fire trucks, and other applications include truck floors and trailer floors. The main alloys are 1100, 1200, 3003, 3105, 5005, 5086, 5052, 5083, 6082, 5251, 5454, 6061 and so on.

1xxx aluminum plate

Among the 1xxx aluminum sheets, there is a specification that is widely used, that is, the aluminum sheet 2mm. In the advertising industry, 2mm aluminum plates are generally used to process signs. Many billboards and signboards we see every day are made of 2mm aluminum plates through engraving, bending, painting and other processes.

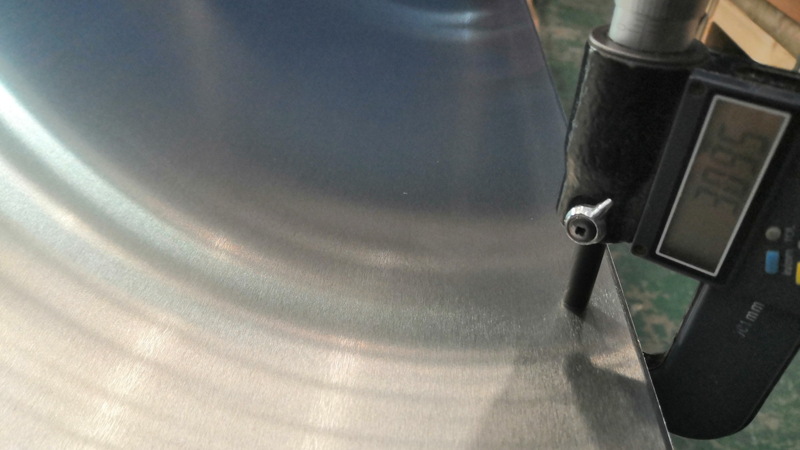

In addition, the 2mm thick aluminum plate is also used as a base plate for kitchen utensils, nameplates and mirror aluminum plates. Among the 2mm aluminum sheets, there are two most widely used grades: 1050 and 1060 aluminum sheets. Please leave a message below to inquire about the price of 2 mm aluminum plate.

How to prevent scratches on the surface of aluminum plate?

Care must be taken when using the forks to feed the profiles from the unloading path to the unloading bed, as many people have caused some damage to the 4x8 aluminum sheet due to excessive speed. Pick up the aluminum divider placed on the bed, do not tug the boat, this will cause damage to the aluminum appearance. There are factors that pass through the damage formation process, which is also the case with aluminum renders that damage renders. Put some small debris on the bed surface of the discharge rail, and then put the aluminum sheet, it will definitely cause damage to the appearance of the aluminum sheet.

Different types of aluminum alloys and their applications

According to the processing method, Alloy Aluminum sheet can be divided into two categories: deformed aluminum alloys and cast aluminum alloys.

Deformed aluminum alloys are further divided into non-heat treatable reinforced aluminum alloys and heat treatable reinforced aluminum alloys.

Cast aluminum alloys can be divided into aluminum-silicon alloys, aluminum-copper alloys, aluminum-magnesium alloys, aluminum-zinc alloys and aluminum-rare earth alloys according to their chemical composition.

There are nine series of deformed aluminum alloys:

1.1000 series

The 1000 series is the series with the most aluminum of all the series. The purity can reach more than 99.0%. Its classics are 1050 aluminum plate and 1060 aluminum plate.

It is characterized by low price, good electrical conductivity and high corrosion resistance. It can be used in the manufacture of electrical appliances, chemical equipment, signs, etc.

2. 2000 Series

The 2000 series is known for its high hardness. The representative is 2024, 2A16, 2A02. The 2000 series belongs to aviation aluminum.

3. 3000 series

The 3000 series belongs to the aluminum-manganese alloy, which is a series with anti-rust function. Its representatives are 3003 aluminum plate and 3A21. It can be used to make water storage tanks, cookware and pipes, etc.

4.4000 series

The 4000 series is a series with higher silicon content. Typically the silicon content is between 4.5% and 6.0%. It has good heat resistance and abrasion resistance. It can be used as building material, machine parts and welding material.

5.5000 series

The 5000 series belongs to the commonly used 4x8 aluminum sheet series. The main element is magnesium, and the magnesium content is between 3-5%. The main features are low density, high tensile strength, high elongation and good fatigue strength, but cannot be heat treated. It is used to make fuel tanks, oil pipes, ship parts, etc.

6.6000 series

The 6000 series contains mainly magnesium and silicon. It is a cold-treated forged product with high corrosion and oxidation resistance. Its representative is 6061 aluminum plate.

It can be used in various industrial structural parts that require high strength, weldability and corrosion resistance, such as trucks, buildings and ships.

Why are the shapes of aluminum lattice panels different?

In fact, aluminum gingham with different patterns and shapes has different aluminum materials.

1. Pattern of compass aluminum alloy plate: non-slip 4x8 aluminum sheet, which is similar to Wujin, but it is not often used.

2. Five-bar aluminum pedal: It has good anti-skid ability and is widely used in construction, platform design, etc. The surface patterns are arranged according to five relatively parallel reliefs, and each pattern has an angle of 60-80 degrees with other patterns, so this pattern has excellent anti-slip performance. It is commonly used in China for anti-skid. Using this, the anti-skid effect is good, and the price is cheaper.

3. Anyone who buys an aluminum plate can call the aluminum plate a hemispherical pattern, and the surface presents a pattern of small balls, like small pearls, so the aluminum plate can be a pearl pattern aluminum plate. Mainly used for packaging. The appearance is more beautiful. Due to the particularity of the pattern, the strength of the Aluminum sheet is much higher than that of other series of patterns.

4. Other aluminum patterns: wave pattern plate, water corrugated pattern aluminum plate, corrugated pattern aluminum plate (aluminum and variable tile), rattan screen pattern aluminum plate, three-dimensional triangular pattern aluminum plate, strip pattern aluminum plate, aluminum pebble pattern plate, aluminum tread pattern Plate, triangular stucco embossed aluminum plate, butterfly pattern aluminum plate, etc.

5052 aluminum plate, 5052 aluminum plate, 5052 aluminum plate

5052 aluminum plate is aluminum-magnesium alloy aluminum, and magnesium is the main alloying factor. Among 5052 aluminum alloys, it is one of the most widely used rust-proof aluminums, and the alloy has high vitality. Specifically, it first has fatigue resistance: plasticity and high corrosion resistance, cannot be strengthened by heat treatment, hardening plasticity is ideal in cold working, although this bloodless painting has low hardening plasticity, correct corrosion resistance, and suitable weldability , the cutting performance is terrible and can be polished.

Aluminum and magnesium alloys contain small amounts of manganese, chromium, beryllium, titanium and many other elements. Small amounts of manganese alloys are more stable solutions, the largest form being MnAl6. This effect of chromium and manganese is comparable in 5052 aluminum, increasing resistance to pressure corrosion cracking, improving base metal and weld vigor, and reducing the tendency for weld cracking, but this material is typically present in amounts not exceeding 0.35 %.

The use of Aluminum sheet is especially used where high plasticity and correct weldability are required, generally used in mobile cars, ship plates, steel components, equipment, lamp brackets and rivets, metal products, electrical enclosures, etc. It can also be used to manufacture aircraft gasoline fuel tanks, oil pipes, and aerospace aluminum alloy cloth. It is a standard anti-rust alloy cloth.

The difference between 3003 and 5002 aluminum plate

3003 and 5052 aluminum plates are the most common alloy 4 x 8 aluminum sheet, but many people do not know the difference between the two. Take 3003 h24, aluminum and 5052 h24 aluminum plates as examples to explain this knowledge.

1. From the chemical composition of 3003 aluminum, it is an aluminum-manganese alloy, and the main alloying element is manganese. 5052 aluminum plate is an aluminum-magnesium alloy, and the main alloying element is magnesium. The aluminum content of 3003 aluminum is slightly higher than that of 5052 aluminum.

2. From the point of view of mechanical properties, the tensile strength of 3003H24 aluminum is 145-195Rm/MPa, while the tensile strength of 5052H24 aluminum is as high as 230-280Rm/MPa, which is much higher than that of 3003H24 aluminum; the tensile strength of 3003H24 aluminum plate is 115Rm /MPa, the tensile strength of 5052H24 aluminum plate is 150Rm/MPa. Therefore, the performance of 5052 aluminum is significantly better than that of 3003 aluminum.

3. The commonly used specifications of 3003 aluminum plate are mainly thin plates, and the application of thick plates is seldom; and 5052 aluminum plates are also widely used in addition to thin plates.

4. In terms of scope, 3003 1/8 aluminum sheet is mainly used in humid environments, such as product packaging, refrigerators, air conditioners, refrigerators, ventilation ducts, etc. The 5052 aluminum plate is often used in electrical enclosures, transportation vehicles, pressure vessels, etc., and is a common material for the manufacture of automobiles, aircraft fuel tanks, and fuel pipes.

The difference between the conductivity of copper sheet and aluminum sheet

What is the difference between 4 x 8 aluminum sheet and copper sheet, and what is the difference in electrical conductivity?

Aluminium article from: Materials and copper are very common in our daily lives.

Aluminum ingots are aluminum products obtained from rolls, which may need to be cut into aluminum of desired widths through different slitting. Aluminum strips are sold according to different uses, and are an important raw material in industry. Aluminum has many uses, such as aluminum-plastic composite pipes, cables, optical cables, transformers, heaters, shutters, etc. Specific uses are: aluminum transformers, transformers, aluminum foil, high-frequency welding hollow aluminum with aluminum fins, aluminum radiators with aluminum, aluminum cables with aluminum, aluminum punching with aluminum, aluminum trim with aluminum, etc. The main aluminum processing equipment is the sub-unit, which can be processed into the required length and width according to the needs. Of course, slitting equipment is common, and can be divided into eight series according to the alloying elements contained in aluminum

As the 1/8 aluminum sheet manufacturer can see from the physical properties of the metal conductive sheet, the electrical conductivity of aluminum is only lower than that of copper, so aluminum strips are becoming an international trend to replace copper strips, so that the raw materials of electronic products are no longer purely dependent on copper strips.

Several common applications of aluminum sheets are introduced

3003 aluminum plate: mainly used for processing parts that require good formability, high corrosion resistance or good weldability. ;

1060 aluminum: cold rods are mainly used in occasions where corrosion resistance and formability are relatively high, but the strength requirements for components are low, such as chemical equipment, marine equipment, railway tankers, conductive materials, etc.;

Alloy aluminum sheets, <a href="https://hw-matels.com/size-aluminum/4x8-metal-aluminum-sheet.php">4 x 8 aluminum sheet</a> for sale, sheets, drawn tubes, extruded tubes, house partitions, roofs, pipes, etc. ;

5052 aluminum plate, sheet, plate, foil, drawing tube, cold-rolled plate, used in the manufacture of aircraft fuel tanks, oil pipes, transportation vehicles, sheet metal parts of ships, instruments, rivet wires for lamp brackets, etc. ;

6061 Aluminum: Aluminum sheet metal, thick material, drawn tube, commonly used in the manufacture of trucks, tower buildings, ships, trams, railway vehicles, furniture, etc. Tubes, rods, profiles.

The difference between aluminum sheet T5 and T6

The forming temperature of the 4 x 8 aluminum sheet extrusion profile is 460 ~ 460 degrees, and the temperature after quenching is generally required to be 200 degrees. Through high temperature extrusion, the solution heat treatment (quenching) is followed by air cooling in artificial aging state (T5); through high temperature cooling extrusion process, water cooling in artificial aging state is then performed (T6).

Aluminum quenching suddenly drops from high temperature to low temperature quenching. For example, steel knife blades should be quenched in water, only hard and sharp. Aluminum quenching has both water-cooled quenching and air-cooled quenching. The 6063 aluminum building is air-cooled and quenched. The quenched aluminum is aged in an aging furnace for a certain period of time, and the internal crystals of the aluminum are rearranged, and the mechanical strength is significantly improved.

Air cooling, T5 is forced extrusion, T6 is water cooling, and the hardness increases after water quenching. However, the diamond-shaped aluminum plate needs to be bent, try not to reach the T6 state,

Some people think that the difference between the 1/8 aluminum sheet T5 and T6 is only part of the difference in cooling speed, not the air cooling water. The difference between the cooling rates of air cooling is large enough to achieve the effect of T6, on the contrary, the cooling rate of water cooling is not large enough, and it can only achieve the effect of T5.

In fact, the T6 state can be quenched online (water or air) or offline (quenched with a quenching furnace), but it depends on the customer's requirements and the product specifications of the aluminum foil manufacturer.

New application areas of aluminum sheets

It is understood that the key areas for expanding the application of ground 4 x 8 aluminum sheet include: transportation, building structures, and electric power. In addition, it also includes aluminum trays, aluminum alloy bridge flood control facilities, aluminum alloys, aluminum foil packaging products and other fields.

Transport sector:

Scope: extended aluminum trailers, convertible aluminum-coal trucks, high-precision aluminum sheet applications for automobiles.

The artistic structure of aluminum plate:

Scope: Expansion Aluminum Alloy Building Formwork, Aluminum Enclosure Application

(1) Expand the application of aluminum alloy building formwork

The amount of aluminum used in domestic formwork continues to grow, and domestic companies also supply aluminum formwork and formwork aluminum to Brazil, India, Venezuela and other countries, as well as Hong Kong and Macao, which will also drive domestic aluminum consumption.

(2) Expand the application of aluminum casing

In domestic civil buildings, large-scale infrastructure projects, especially large-span and complex-shaped projects, such as airport terminals, exhibition centers, stadiums and other public buildings, have widely used 3003 Aluminum Sheet for the roofs and walls. However, in industrial buildings, the steel structure sheet metal enclosure system accounts for about 70% of the total building, and aluminum is less used.

electric field:

my country's copper resources are in short supply and need to be imported in large quantities. The proportion of copper in the field of electricity consumption accounts for more than 40% of the total consumption. my country has formed a strong industrial base 5052 aluminum plate resources, replacing the insufficiently protected copper resources, to a certain extent, it can reduce the external dependence of my country's copper resources and enhance the resource security capability.