Thin aluminum sheet for lighting

Thin aluminum sheets are used in the lighting industry for their light weight, low cost, long life and high quality. Sheet aluminum manufacturers have many customers who manufacture aluminum lamps, lamp shades, circuit boards, and more. Sheet aluminum has 1060, 1070, 1100, 3003 and 5052 alloys. The following describes the application of thin aluminum sheets in this regard.

Application range of thin aluminum sheet in lighting:

1. Aluminum plate 3104 is used as lamp sockets for incandescent lamps and fluorescent lamps, and other thin aluminum plate materials have become routinely used as sockets.

2. Casting, stamping and spinning aluminum parts are often used for artistic decoration of lamps such as table lamps and floor lamps.

Aluminum plate reflectors are common for fluorescent lighting systems and other lighting installations.

4. In recent years, solar energy-saving lamps have been widely promoted and used, and their lampshades, sockets, brackets, connecting rods, etc. All use Quality Alloy Aluminum Sheet profiles or pipes.

Advantages of thin aluminum sheets as lighting materials for lamps

1. Aluminum sheet can reduce the load of lamps. For example, a lamp post in an open-air sports field requires 80 spotlights. Lightweight aluminium lamps show their advantages.

2. The service life of outdoor lamps is required to be more than 10 years, and the aluminum alloy lampshade with good corrosion resistance can meet this requirement. Their surface is anodized, which not only improves hardness and wear resistance, but also allows for frequent scrubbing and a decorative finish.

3. In order to reduce weight and save energy, transportation vehicles also use aluminum wires, aluminum coils and aluminum electrical components. At present, aluminum alloys with good flexibility and creep resistance and effective low-voltage (12V) electrical contact materials have been developed.

4 x 8 price of aluminum plate

4 x 8 aluminum sheets are the best-selling alloy aluminum sheets on the market, with alloys ranging from 1000 series to 8000 series. Therefore, the price of the national standard 4 x 8 aluminum sheet on the market must be of concern to everyone. Huawei Aluminum will analyze the market price of aluminum sheets for you.

1. Specifications and quality are fundamental

Specifications and quality affect the price of 4 x 8 aluminum plate is ultimately reflected in the specification and quality of the alloy. The aluminum plate market tends to be saturated. Under the competition, the price of 5052 aluminum plate is lower than that of 6061 aluminum plate and 6063 aluminum plate, while 6061 aluminum plate is a hot-selling product in the market, with strict process requirements, relatively few manufacturers, and the price is naturally more expensive. There are many 5052 Aluminum Sheet manufacturers, and the market is relatively saturated, so the price of 5052 aluminum plate is relatively cheap.

2. 4x8 aluminum sheet manufacturer is the key

At present, there are many 8x4 aluminum plate manufacturers in China, and there are hundreds of aluminum plate manufacturers in China alone. Among these manufacturers, the scale, nature and strength of the manufacturers are different, and the quotations for aluminum sheets are naturally different. It is recommended that consumers buy products from large, direct-selling, and powerful manufacturers, because these manufacturers have advanced equipment, high technology, better quality, and more reasonable prices.

3. Direct cost factors

The level of cost will directly affect the price level of 48 aluminum sheets. In the production process, it is inevitable to spend a certain amount of investment in manpower, material resources and technology. The higher the cost of 4x8 aluminum plate manufacturers in this regard, the higher the price.

High quality hot rolled steel sheet

Hot-rolled sheet, also known as hot-rolled sheet or hot-rolled steel plate, refers to an aluminum sheet product processed by a hot rolling mill. Usually, hot-rolled aluminum sheets are made from 4 x 8 aluminum sheet with a thickness of 400-500 mm that are processed multiple times by a hot-rolling mill. Due to the higher pressure during processing, the internal structure is more uniform and the grain size is better. The microstructure of the hot-rolled aluminum sheet is more uniform and dense. After anodizing, the surface texture of the hot-rolled aluminum plate is consistent, without ripples and color difference.

In the process of hot-rolled sheet processing, it is necessary to reasonably control the metallographic structure, mechanical properties, surface quality and geometric size and shape of the hot-rolled aluminum sheet to meet the quality requirements of subsequent processing and final products. In the hot rolling process of aluminum and aluminum alloys, the change of microstructure is a very complicated process. First, the grains of the material are deformed under the action of the strong rolling force, the as-cast grains are flattened, and the grains of the material are flattened along the rolling direction, while being elongated and strain hardened, and then dynamic recovery and dynamic regeneration may occur. crystallization.

Hot-rolled sheet products are generally divided into two categories, one is hot-rolled thick aluminum plate, and the other is hot-rolled aluminum coil. Hot-rolled thick aluminum plate refers to an aluminum alloy plate with a thickness of not less than 6.0 mm. The main varieties are hot-rolled plate (H112), annealed plate (O), quenched or quenched pre-stretched plate, etc. Hot rolled 1/8 aluminum sheet are usually used in hot rolling mills. It is produced by the block method, and its typical process is: ingot (homogenization) milling, edge rolling, heating, hot rolling, shearing, interruption, straightening.

Aluminum alloy sheet 5083

Aluminum alloy sheet 5083 is a typical product of 5000 series anti-rust and anti-corrosion aluminum-magnesium alloy. In hull materials such as spe edboats, 5083 Aluminum Plate has sufficient strength and rigidity, and at the same time can reduce weight, resist seawater corrosion, and have good weldability. For example, large anti-submarine wing research ships and PTF-class speedboats are all 5000 series aluminum-magnesium alloy structures. In 1976, the all-welded aluminum structure of the US Navy also used 5083 aluminum plate and 5456 aluminum alloy as the main material. Since then, the British and French navies have separately built aluminum hulled catamarans. Aluminum alloy hulls have also become popular in Norway, Sweden, Japan and other countries.

Aluminum alloy plate 5083 is mainly used in the marine industry for shipbuilding and shipbuilding. 5083 aluminum plate is generally tempered by H116/H321/H112, and the length and width are 2 meters x 6 meters. Aluminum plate 5083 alloy has high toughness, corrosion resistance and weldability, which provides a good choice for building ships with strict weight requirements. Huawei Aluminum is one of the leading 8x4 Aluminium Sheet manufacturers in China, 5083 aluminum sheet is also our company's key product, we have rich experience in manufacturing and exporting 5083 aluminum alloy sheet, and we enjoy a high reputation among global customers.

5083 aluminum alloy sheet as a shipping material can effectively reduce the weight of the ship and increase the speed of the ship. In order to reduce the water resistance, our country's marine grade aluminum plate research and development technology is mature, and the ship plate level of some manufacturers has reached the international advanced level. In addition, my country has superior water transportation conditions and rich coastline resources. With the development of economy and trade, the demand for ships is increasing, and transportation materials such as aluminum alloy ships are also developing rapidly. Marine-grade aluminum sheet manufacturers should seize this opportunity, focus on marine aluminum alloy materials, seize market opportunities, and develop the international marine market.

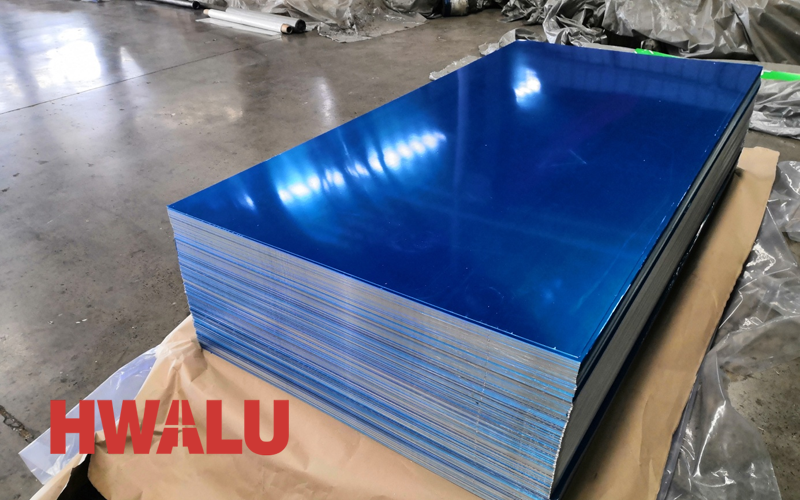

4x8 Aluminum Sheet Supplier

Huawei Aluminum is a leading supplier and manufacturer of 4x8 aluminum sheets, mainly dealing in 1000 series, 3000 series, 5000 series, 6000 series and other series of aluminum sheets. Among them, the main products are 1060 aluminum plate, 3003 aluminum plate, 5052 aluminum sheet, 6061 aluminum plate, 7075 aluminum plate and so on. Very popular with users. Especially for honeycomb aluminum plate, perforated aluminum plate, aluminum pattern plate, anodized aluminum plate, carved aluminum plate, color aluminum plate, curtain wall aluminum plate and other customers. At the same time, our aluminum sheets are cheap and stable in quality.

As a 4x8 aluminum sheet supplier, Huawei Aluminum insists on using excellent and stable products and provides comprehensive and thoughtful services to provide excellent and stable aluminum sheets for the majority of aluminum sheet users. We have reached an annual production capacity of 200,000 tons, with the advantages of fast delivery time and stable quality! We look forward to establishing a cooperative supply relationship with you for 4x8 aluminum sheet products. At the same time, you are welcome to visit our factory!

From 1000 series and 3000 series aluminum plates commonly used by 4x8 aluminum sheet suppliers, to 6061 alloy aluminum plates for die stamping, etc. , they are widely used. But the aluminum alloy plate generally refers to, such as 6061 alloy aluminum plate, 5052 alloy aluminum plate, 5083 alloy aluminum plate, 3003 aluminum plate and so on. , is actually an aluminum alloy plate. In fact, by carefully analyzing the alloy composition of the aluminum alloy sheet, we must not be difficult to find a very important point, that is, they are all alloys of aluminum itself. Add various total amounts to the difference in alloy composition to achieve the purpose of strengthening, or to change some of its own differences.

Trailer shell aluminum plate

The advantage of trailer skin aluminum is light weight but high strength. That is to say, under the same strength, the weight of the aluminum trailer is small. In other words, an aluminum trailer is stronger for the same weight. In aluminum alloy trailers, the structural requirements are particularly important. For example, in some places that need to bear relatively large forces, extruded profiles must be used to bear the weight. The use of aluminum sheet to manufacture trailer skin has huge economic and social benefits, and it is also the main reason for reducing the use of lightweight aluminum. Trailer aluminum plate application: 5000 series alloy: 5182 aluminum plate, 5083 aluminum plate, 5086 aluminum plate, 5052 aluminum sheet, 5454 aluminum plate, 5754 aluminum plate, 6000 series alloy: 6061 aluminum plate, 6063 aluminum plate, 6082 aluminum plate.

The side and inner panels of the trailer skin are 5052 alloy aluminum sheets with a thickness of 4-5 mm. The trailer body consists of aluminum alloy sheets and extruded aluminum profiles. The aluminum profile is used as a column, which is thicker in the middle and has a flange. The thickness of the flange is equal to the thickness of the aluminum alloy plate, the butt joint of the aluminum alloy plate is located at the reinforcing rib, and the upper and lower sides of the aluminum alloy plate are supported on the flanges of the upper and lower beams of the aluminum profile. In addition, 2.5mm, 3mm, 4mm and 5mm anti-skid aluminum pedals are usually used for trailer floors, and the application of anti-skid aluminum gratings in automobiles is also increasing year by year. The use of trailer aluminum plates can reduce the overall quality of the trailer to a certain extent, and realize the lightweight of the trailer body, thereby reducing carbon dioxide emissions, improving fuel efficiency, and ensuring energy saving to a greater extent.

Trailer skin aluminum has better toughness and better resilience. Lighter weight can be used to load cargo, creating more profit. This is also the biggest selling point of aluminum alloy trailers. Under normal load conditions, the aluminum alloy can fully meet the use requirements. Aluminum alloy plate has good oxidation resistance, corrosion resistance and excellent rust resistance. The finished 4 x 8 aluminum sheet for the trailer housing can last a long time. Aluminum alloy is easy to recycle and more environmentally friendly.

8011 Other uses of aluminum foil other than medicinal

8011 aluminum foil is a common material of aluminum foil. It is usually used in medical packaging, tape foil,

lunch box aluminum foil, food packaging, beer sealing foil, barbecue aluminum foil, etc.

The usual state is 8011-0 state (soft), and the surface of 8011 aluminum foil is clean and bright.

Even, no spots, flat and no pinholes. It has excellent moisture resistance, shading and extremely high barrier ability,

strong mechanical properties, high blast resistance, strong puncture resistance and tear resistance.

Non-toxic, tasteless, safe and hygienic. The aluminum foil after compounding,

printing and gluing is widely used as a packaging material

8011 medicinal aluminum foil has excellent moisture resistance, shading advantages and high blocking ability.

Strong mechanical properties, good shear and tensile properties, easy to process.

It has good corrosion resistance and has a certain ability of stress corrosion cracking.

8011 aluminum foil is used for pharmaceutical packaging: PTP pharmaceutical aluminum foil,

cold stamping pharmaceutical foil, 8011-H18 aluminum foil for pharmaceutical packaging,

capsule aluminum foil board, etc. Advantages: high cupping value, high aluminum foil strength, good sealing;

In addition to medicinal uses, 8011 aluminum foil has some other conventional uses:

used for food preservation, barbecue, aviation, hotel catering and kitchen cleaning, and after printing or painting,

Aluminum foil packaging of dairy products such as fresh milk and yogurt. .

On the packaging of pharmaceutical capsules, tablets, granules.

It is suitable for all kinds of transformers, mobile phones, computers,

PDAs, PDPs, LED monitors, notebook computers, copiers and other electronic products where electromagnetic

shielding is required.

Bottle caps: Liquor bottle caps, red wine bottle caps, cosmetic bottle caps, milk powder caps,

pharmaceutical caps, beverage caps, yogurt caps, etc. Advantages: water-washing grade A, low ear-making rate;

8011 aluminum foil is used for food packaging: food packaging, heat sealing foil, lunch box material,

container foil, aluminum foil gasket for sealing; Advantages: clean surface without foreign matter, guaranteed hygiene;

8011 industrial aluminum foil: aluminum foil for transformer, aluminum foil tape,

aluminum foil for cable tape, aluminum foil for filter; advantages: clean oil removal, flat plate shape;

Marine aluminum alloy 5083 sheet

Marine 5083 aluminum alloy plate is a common product in marine 5083 Aluminum Plate for shipbuilding. Aluminum boat structure, the hull is made of aluminum alloy, 5083 aluminum plate, the dock is made of aluminum alloy buoy & # 8211; the deck is made of 5083 aluminum plate and aluminum alloy checkered steel plate (5052 aluminum plate is used). Considering the light weight of the hull, thin aluminum sheets should generally be used as much as possible, but the depth of corrosion of the aluminum sheets during service should also be considered.

Generally, the marine aluminum alloy 5083 plate is a thin plate above 1.6 mm and a thick aluminum plate above 30 mm. In order to reduce welding, large ships often use marine grade aluminum plates with a width of 2.0m and 5083 aluminum plates with a width of 2.5m. The length is generally 6m, and some special specifications are also adopted according to the shipyard contract. To prevent slippage, the deck is made of checkered aluminum. 5083 aluminum alloy sheet is considered to be a typical marine grade aluminum sheet product line along with 5052 aluminum sheet, 5086 aluminum sheet, 5454 aluminum sheet and 6061 aluminum sheet.

Marine 5083 aluminum alloy sheet can be divided into aluminum alloy for hull structure and aluminum alloy for outfitting according to the purpose. The aluminum alloys used in the hull structure are mainly 5083, 5086, and 5456. Due to intergranular corrosion in seawater, 6000 series alloy aluminum sheets are mainly used in the superstructure of ships. This is an extruded profile. 5000 series alloy aluminum plate has superior strength and process performance after heat treatment, and has broad application prospects in the field of shipbuilding. Mainly used for the superstructure of ships, such as extruded structures, steel plates, etc.

The secret of 1070 aluminum plate

Aluminum is an amazing metal on earth. It is strong, light, durable, flexible, versatile, waterproof, corrosion resistant, excellent electrical conductor, non-magnetic, non-flammable, and is the shell of the infinitely circulating abundant elements in the earth. Aluminum has unlimited potential, so in daily life and industry, we can see many products about aluminum everywhere. Among so many aluminum products, we will introduce you a typical aluminum sheet & # 8212; 4 x 8 aluminium sheets.

1070 aluminum plate is a material used to manufacture certain structures with specific properties. It has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity. However, the strength of 1070 aluminum plate is low, it cannot undergo intensive heat treatment, and its cutting performance is poor, so it cannot accept contact welding and gas welding. In practical applications, people usually take advantage of its advantages to produce structures with more specific properties, such as aluminum foils are made into gaskets, capacitors, valve isolation nets, wires, cable protective jackets, net parts and decorative materials, wire cores, and aircraft ventilation system. The aluminum content is as high as 99.7%, and it is a pure aluminum product. Other contents are: copper: 0.04%, manganese: 0.03%, magnesium: 0.03%, zinc: 0.04%, titanium: 0.03%, vanadium: 0.05%. As we all know, the aluminum market is not stable relative to other industries, especially the price, which changes almost every day, so the price of 3mm aluminium sheet price changes with the price of aluminum. 1070 aluminum plate is the most commonly used series, the production process is simple and fast, the technology is mature, and the price has a huge advantage over other high-grade aluminum alloys. 1070 aluminum plate has good elongation, formability and tensile strength, which can fully meet the requirements of conventional processing. If you want to buy pure aluminum plate, 1070 aluminum plate is a good choice!

What is Cold Formed Blister Aluminum?

Cold stamping aluminum (also known as hard double aluminum) is currently the best medicinal hard sheet

with the best barrier properties, which can almost completely block water vapor, oxygen, ultraviolet rays,

and has excellent fragrance retention properties. Each blister forms an independent unit that completely isolates water vapor,

oxygen, and ultraviolet rays, and takes out part of the contents of a tablet without any influence on other well-packaged

drugs in the same tablet.

The general structure of cold-formed small blister is: NY25/AL45/PVC60;

the general structure of cold-formed large blister is: NY25/AL60/PVC60

The characteristics of cold-formed blister aluminum are: good barrier properties, completely blocking water vapor,

oxygen, ultraviolet rays, and excellent fragrance retention.

Cold-formed blisters are mainly used for drugs that are sensitive to moisture,

or that need to be protected for sale in hot and humid areas. By changing the mold,

it is very convenient to design and manufacture beautiful and various shapes.

In addition, its unique gorgeous silver-gray color adds to the attractiveness of the packaged product,

which can greatly promote the sales of the product.

Cold stamping aluminum packaging has been Become synonymous with high-end medicines.