1100 Aluminum Sheet Plate H12 14 H16 H18 H22 H24

Specifications of Aluminum Alloy Sheet:

1. Grade

1000 Series: 1050 1060 1070 1100 1200 1235 etc.

3000 Series: 3003 3004 3005 3102 3104 3105 3A21 etc.

5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc.

6000 Series: 6061 6063 6082 6A02 etc.

7000 Series: 7050 7075 7475 etc.

8000 Series: 8006 8011 8079 etc.

2. Thickness: 0.20mm-320mm

3. Width: 8mm-2400mm

4. Length: 1220 or per customer's request

5. Temper: all tempers, H1X, H2X, H3X, O, HXXX

6. Continuous casting and hot rolled both available

Manufacture of aluminum alloy plate:

Ingot + master alloy → smelting → holding furnace → continuous casting → cold rolling (intermediate annealing) → horizontal shearing → annealing → aluminum plate

Application of 4 x 8 aluminum sheet:

1. Planes, cars, trains

2. Building walls, ceilings, roofs, furniture cabinets, lighting panels

3. Ship board, solar reflector, corner guard, thermal insulation material

4. Beverage bottles, bottle caps, pull tabs, cosmetic casings and caps

5. Aluminum tread/embossed sheet, quenched and pre-stretched sheet

6. PS substrate, CTP substrate, sign, nameplate

7. Electrical product shell, construction machinery sheet

8. Aluminum reefer containers and special containers, etc.

9. Rotation, automatic, etc.

What Is 3003 Aluminum Used for

3003 aluminum is a common kind of Al-Mn Series Alloy. Owing to Mn element, 3003 aluminum is of excellent rust-proof properties and is also known as rust-proof aluminum.

It is easy to bend and of good weldability properties,formability and solubility. It is an alloy that is not heat treatable and can only develop strength from cold working. The strength of 3003 4x8 aluminum sheet is about 10% higher than 1100. It also has high plasticity in the annealing state, good plasticity in the semi-cold hardening state, and low plasticity in the cold hardening.

What Is 3003 aluminum used for? Because of these 3003 aluminum properties, 3003 aluminum is mainly used for low load parts requiring high plasticity and good weldability in liquid or gaseous media, such as fuel tanks, gasoline or lube oil conduits, various liquid containers and other small load parts made with deep drawing.

The common forms of 3003 aluminum is 3003 aluminum foil, 3003 aluminum sheet and plate. Because of its excellent rust-proof properties, 3003 aluminum foil is often used in wet environments like outer packaging, refrigerator, air conditioning ventilation ducts,etc.

3003 aluminum sheet is commonly used in boats, naval ships, automobile and aircraft welded parts, pressure vessels, refrigeration equipment, television towers, drilling equipment,missile components, armor, etc.

As a professional aluminum sheet manfuacturer, plate and foil, Haomei can offer you 3003 aluminum sheet with best price and air conditioner foil of different specifications.

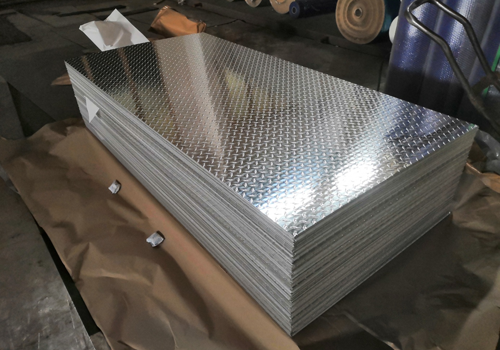

Different uses of patterned aluminum sheets

Aluminum pedal patterns include five strips, diamond, orange peel, three strips and small five strips. Orange peels, diamonds, domed motifs and pearls are highly decorative. Among them, the orange peel pattern 4x8 aluminum sheet has a good contact area, and is often used in refrigerators, air conditioning refrigeration, and pipeline anti-corrosion and heat preservation.

The 5-stripe aluminum pedal has a strong anti-skid effect due to the obvious concave-convex pattern. Commonly used in automobiles, passenger cars, trucks, Iveco, ships, equipment platform treads, stair treads, cold storage floors, etc. Because it is an aluminum skirting board, the surface is bright, corrosion-resistant, and will not rust. There are other aluminum pedal patterns, customized according to customer's special requirements.

According to the alloy, it can be divided into ordinary pattern aluminum plate, aluminum-magnesium-aluminum plate, and aluminum-magnesium-aluminum plate. Ordinary pattern aluminum plate is processed on the basis of 1060 aluminum plate, which can adapt to ordinary environment and is cheap.

The aluminum-manganese tread plate is made of 3003 Aluminum Sheet, the strength is slightly higher than that of ordinary aluminum plate, and it has certain anti-rust performance, but the hardness and corrosion resistance are not very high.

The aluminum-magnesium material is 5052 or 5083 aluminum pedals, which have good corrosion resistance, hardness and rust resistance. It can usually be used in places with a certain load-bearing capacity.

Huawei Aluminum has adopted an advanced grinding machine to ensure that the rolling mill can be ground regularly and meticulously, so that the rolling equipment runs accurately and the surface quality of the product is improved. Huawei pattern aluminum plate is about 7kg per square meter, and the tensile strength is 200N per square millimeter.

In addition, the aluminum pedal has a high elongation with a relative elongation higher than 10%. Can withstand high bending without breaking, good toughness. Welcome to leave a message below to inquire about the price of pattern aluminum treads.

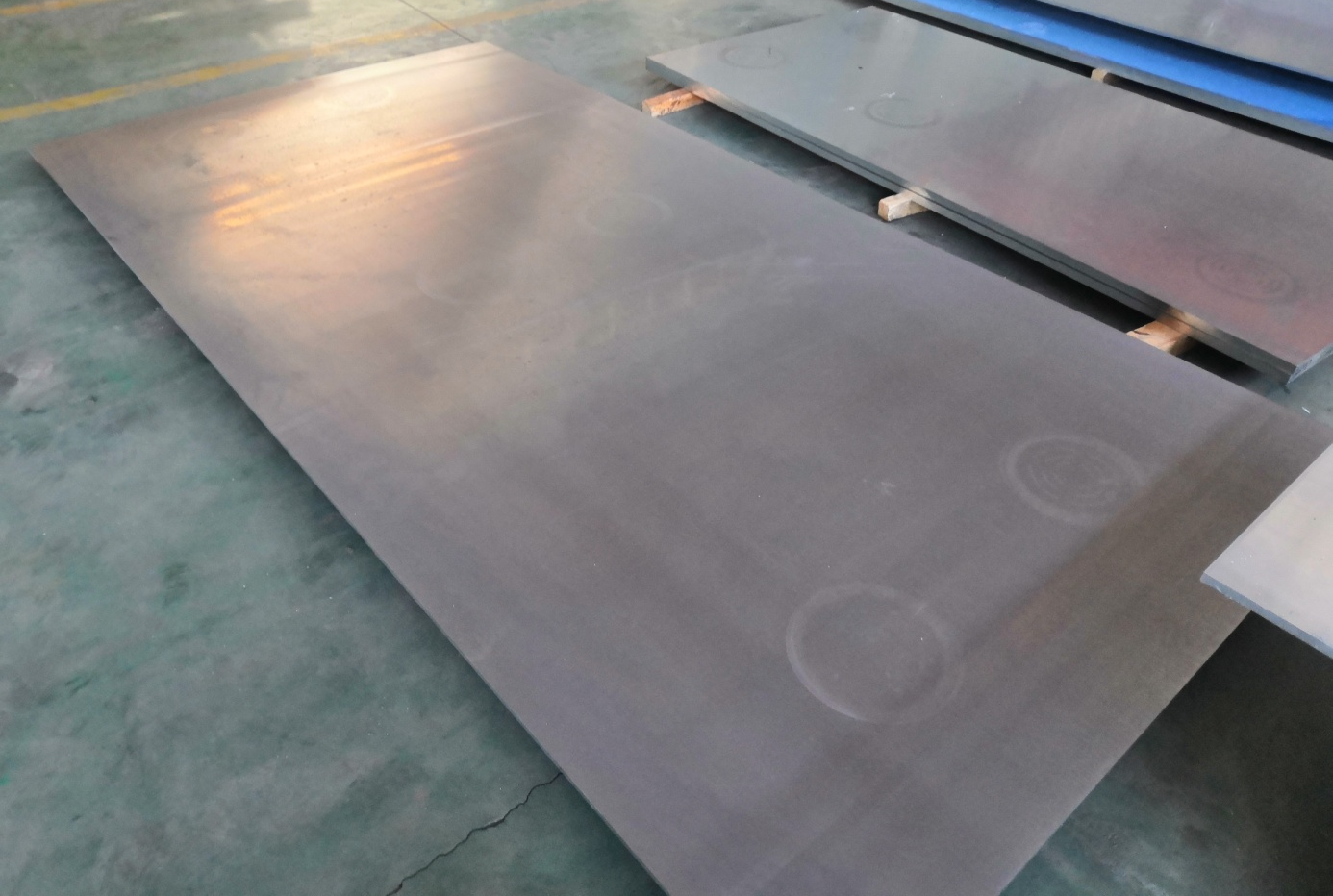

Factory Packing of Aluminum Sheets and Sheets

First, place the aluminum and aluminum sheets on the plank, aligning the edges.

Then, cover the steel plate with high-quality kraft paper

Finally, secure the kraft paper with packing tape, and a perfect package is created.

Alloy number of aluminum plate and aluminum plate:

1000 series: 1050 1060 1070 1100 1200 1235

3000 series: 3003 3004 3005 3105 3A21

5000 series: 5052 5083 5086 5754 5251

Specifications of aluminum plate and aluminum plate:

Thickness: 0.15mm-350mm

Width: 200mm-3000mm

For more technical information about aluminum sheet and 4 x 8 aluminum sheet products, please contact our friendly professional manager (augustao mei-aluminum ) for expert help to find the product that meets your needs.

An important link in the processing of aluminum plate manufacturers

Aluminum products are processed by 4 x 8 aluminum sheet manufacturers through aluminum anodizing technology, which greatly improves wear resistance, corrosion resistance, light resistance, weather resistance and other properties, and can have a variety of beautiful and bright colors. It adapts to the requirements of the aesthetic feeling of the times, thereby greatly improving the application value of the aluminum plate.

Decorative aluminum sheet building profiles are the main materials for doors, windows and curtain wall structures and are widely used around the world. The aluminum alloy extruded profile (without surface treatment) has a single appearance and is easy to corrode in a humid atmosphere, so it is difficult to meet the requirements of high decoration and strong corrosion resistance of building materials.

In order to improve the decorative effect, enhance the corrosion resistance and prolong the service life, the aluminum plate usually needs to be surface treated. Therefore, aluminum anodizing surface treatment is an essential and extremely important process in the production of aluminum alloy profiles. The oxide film formed by anodization of aluminum alloy in -H2SO4 solution is white, transparent, high in porosity and good in chromaticity, especially suitable for aluminum oxidation processing.

What is the use of 2mm thick aluminum plate

Different applications have different requirements for the thickness of Aluminium Products Manufacturer in China sometimes. Common aluminum plate thicknesses are 1, 2, 3, 4, 5, 6, 8, 10, 15 mm, etc. , especially the 2mm aluminum plate. For the same alloy, 2mm aluminum sheets are also cheaper. Let's see its common usage.

road sign

Circular and triangular traffic sign materials generally use 1.2 mm, 1.5 mm and 2 mm aluminum plates. For large road signs and highway signs, aluminum sheets with a thickness of 2.5 or 3 mm are required. 1060 or 3003 aluminum sheets are common choices.

Aluminum solid plate

The aluminum solid board can choose different thicknesses according to different architectural decoration requirements. The conventional thickness is 1.5mm, 2.0mm, 2.5mm, 3.0mm, the thickness of aluminum plate for outdoor building decoration is generally 2.5mm, 3mm; the thickness of 2.0mm can be selected for indoor decoration; the thinnest 1.5mm can be selected for indoor ceiling decoration.

shipbuilding

Marine aluminum plate generally refers to aluminum-magnesium alloy. At present, the commonly used aluminum plate is 5083 aluminum plate, such as 5083H116 aluminum plate and 5083H321 aluminum plate. Common thicknesses are 2 mm, 3 mm, 4 mm, 5 mm, 6 mm, 8 mm, 10 mm, etc.

aluminum body

On the premise of ensuring the rigidity, strength and safety performance of automobiles, by changing the materials of automobile structures and parts, lightweighting helps to improve the fuel efficiency of automobiles and reduce pollutant emissions. 5052 aluminum sheets with a thickness of 2 mm are usually used for the front and rear panels of automobiles.

aluminum pedal

Aluminum pedals reduce the risk of slipping. It is commonly used in stairs, walks, walkways, ramps, ambulance and fire truck treads, and other applications include truck floors and trailer floors. The main alloys are 1100, 1200, 3003, 3105, 5005, 5086, 5052, 5083, 6082, 5251, 5454, 6061, etc.

1xxx aluminum plate

Among the 1xxx aluminum sheets, there is a specification that is widely used, that is, the aluminum sheet 2mm. In the advertising industry, 4 x 8 aluminum sheet are generally used to process signs. Many billboards and signboards we see every day are made of 2mm aluminum plates through engraving, bending, painting and other processes.

In addition, the 2mm thick aluminum plate is also used as a base plate for kitchen utensils, nameplates and mirror aluminum plates. Among the 2mm aluminum sheets, there are two most widely used grades: 1050 and 1060 aluminum sheets. Please leave a message below to inquire about the price of 2 mm aluminum plate.

5083 aluminum plate for tank car

5083 aluminum plate is the main alloy used in tank trucks, and high-quality 5083 aluminum plate is the guarantee of transportation safety. The tank body is the core of the tanker industry. When choosing a high-quality tanker, the material of the tanker is the main reference factor. There are differences in the quality of the 5083 aluminum sheet as a tanker material, which will affect the procurement of tankers. The selection of high-quality tanker materials can reflect the comprehensive strength of tanker manufacturers. At the same time, this will improve the safety of transport and in some ways save lives.

5083 aluminum plate for tank car

At present, domestic tank trucks usually use 5083 aluminum plates, the length is within 12.5 meters, the width is within 2.2 meters, and the thickness is usually 5 mm, 6 mm and 8 mm, and a complete tank needs 4-6 pieces of 5083 aluminum plates. More importantly, the most important tank body is made of 5083-H111 aluminum plate, and the can lids on both sides are made of 5083-O aluminum plate. O tempering is softer, and the lid needs to be curved, so the separator is also made of 5083-O aluminum plate. However, some manufacturers still use H111 tempered 5454 aluminum sheets to produce tank car bodies. Mingtai Aluminum Co., Ltd. can also provide this.

In China, Huawei Aluminum is the most competitive 4x8 sheet of 1/8 inch aluminum price manufacturer. Huawei Aluminum's 5083 aluminum sheets have been sold to the United States, Canada, Brazil, Chile, Mexico, Colombia, Argentina, Germany, the United Kingdom, Italy, Spain, Bulgaria, the Netherlands, Serbia, Ukraine, Saudi Arabia, the United Arab Emirates, Iran, Bangladesh, Tunisia , Algeria, Nigeria, South Africa, Ghana, India, Vietnam, Thailand, South Korea, Singapore, Indonesia, Philippines, Australia, New Zealand, East Timor and more than 60 countries around the world. Our products have been sold abroad and won high praise from customers. Huawei Aluminum has an advanced technical team, strict quality control team and service system, all of which ensure that our products can meet international standards. Rich experience also makes Huawei Aluminum have a good reputation in China.

The company consists of two main production bases, one is located in Gongyi City and the other is located in the High-tech Industrial Development Zone of Zhengzhou City, Henan Province, covering an area of 250,000 square meters. Huawei Aluminum has more than 2,600 employees, 10 continuous casting production lines and more than 44 other large-scale processing equipment, with an annual output of 650,000 tons. In addition to 5083 aluminum sheet, Huawei Aluminum can also produce other aluminum sheets, aluminum foils, and aluminum coils from 1000 series to 8000 series.

An important link in the processing of aluminum plate manufacturers

Aluminum products are processed by aluminum sheet manufacturers through aluminum anodizing technology, which greatly improves wear resistance, corrosion resistance, light resistance, weather resistance and other properties, and can have a variety of beautiful and bright colors. It adapts to the requirements of the aesthetic feeling of the times, thereby greatly improving the application value of the aluminum plate.

Decorative 4 x 8 aluminum sheet building profiles are the main materials for doors, windows and curtain wall structures and are widely used around the world. The aluminum alloy extruded profile (without surface treatment) has a single appearance and is easy to corrode in a humid atmosphere, so it is difficult to meet the requirements of high decoration and strong corrosion resistance of building materials.

In order to improve the decorative effect, enhance the corrosion resistance and prolong the service life, the aluminum plate usually needs to be surface treated. Therefore, aluminum anodizing surface treatment is an essential and extremely important process in the production of aluminum alloy profiles. The oxide film formed by anodization of aluminum alloy in -H2SO4 solution is white, transparent, high in porosity and good in chromaticity, especially suitable for aluminum oxidation processing.

Where Can I Buy Aluminum Sheet Metal

Where Can I Buy Aluminum Sheet Metal

Considering where to buy aluminum sheet metal? Please look at HUAWEI Aluminum as your aluminum sheet manufacturer! HUAWEI Aluminum provides 1000-7000 series of China Marine Grade Aluminum Sheet, super large-format CNC machining equipment to assist aluminum plate processing, professional technical engineers provide design drawings, mold proofing, processing and production, and super-perfect pre-sales and after-sales consultation, so that you have no worries!

After 25 years of production, processing and sales of aluminum sheets and other materials, HUAWEI Aluminum has provided thousands of enterprises and units with high-quality aluminum sheet metal products and services. Customers generally praise. No matter what the processing requirements are, please state them first. We, HUAWEI Aluminum, will provide the processing plan that meets the expectations as much as possible according to our own equipment configuration and technical reserves. How does HUAWEI Aluminum ensure the quality of the aluminum sheets it sells?

1. Provide original material proof

2. Provide third-party inspection agencies such as SGSBV to provide inspection

3. Sign the purchase contract and provide the goods in strict accordance with the contract

4. Review and check before leaving the warehouse to ensure that the product will not go wrong

5. The product should be carefully packaged before leaving the warehouse to ensure that it will not be damaged during transportation.

Where Can I Buy Aluminum Sheet Metal

Considering where to buy aluminum sheet metal? Please look at HUAWEI Aluminum as your aluminum sheet manufacturer! HUAWEI Aluminum provides 1000-7000 series of 4x8 aluminum sheet, super large-format CNC machining equipment to assist aluminum plate processing, professional technical engineers provide design drawings, mold proofing, processing and production, and super-perfect pre-sales and after-sales consultation, so that you have no worries!

After 25 years of production, processing and sales of aluminum sheets and other materials, HUAWEI Aluminum has provided thousands of enterprises and units with high-quality aluminum sheet metal metal products and services. Customers generally praise. No matter what the processing requirements are, please state them first. We, HUAWEI Aluminum, will provide the processing plan that meets the expectations as much as possible according to our own equipment configuration and technical reserves. How does HUAWEI Aluminum ensure the quality of the aluminum sheets it sells?

1. Provide original material proof

2. Provide third-party inspection agencies such as SGSBV to provide inspection

3. Sign the purchase contract and provide the goods in strict accordance with the contract

4. Review and check before leaving the warehouse to ensure that the product will not go wrong

5. The product should be carefully packaged before leaving the warehouse to ensure that it will not be damaged during transportation.